3-Axis MicroBlock™ Compact Flexure Stages

- 4 mm of Travel per Axis

- Differential or Thumbscrew Drives

- Thermally Stable Design Minimizes Drift

MBT602

Compact Flexure Stage

Thumbscrew Drives

MBT616D

Compact Flexure Stage

Differential Micrometer Drives

US Patent 6,186,016

RB13P1

Additional Top Plate for Off-Center and General Optics Mounting

Please Wait

Features

- 4 mm of X, Y, and Z Travel

- Flexure Design Ensures Smooth Continuous Motion and Long-Term Stability

- Compact Size: 77.5 mm x 74.0 mm (3.05" x 2.91") Not Including Drives

- Grooved Top Plate Ensures Alignment of Multi-Axis Stage Accessories

- All Adjusters Coupled to the Base to Minimize Crosstalk

- Flexure Translation Prevents Friction Reducing Drift when Compared to Roller Bearing Design

Thorlabs' 3-axis MicroBlock™ Compact Flexure Stages are ideal for use in fiber launch systems or applications that require micron resolution. The parallel flexure design yields three orthogonal linear translation degrees of freedom without the severe limitations of stiction and friction that are found in traditional bearing-based stages. The use of nested flexure plates allows this stage to operate indefinitely without the need for any lubricant, which is one of the primary sources of drift within positioning devices.

Each unit provides 4 mm (0.16") of X, Y , and Z travel with a maximum load capacity of 1 kg (2.2 lbs). The nominal deck height of the stage is 62.5 mm (2.46"), which matches that of our 3-Axis MicroBlock compact flexure stages and RollerBlock long-travel stages, as well as that of our MVSN1(/M) motorized vertical stage. Adapter plates are available for mounting our NanoMax stages to a wide range of other Thorlabs long-travel linear stages.

Click to Enlarge

Figure 1.3 HCS013 Objective Mount and HFF001 Quick-Release Fiber Clamp Accessories Attached to the Top Plate and AMA009 Bracket Using AMA010 Cleats for Fiber Launch Applications

Click to Enlarge

Figure 1.4 AMA554 Height Adapter can be Used to Raise the Deck Height to 112.5 mm, Matching Our

6-Axis NanoMax Stages

Precision Drives

The MBT616D stage includes compact differential adjusters that offer 50 µm travel per revolution over the 300 µm fine adjustment range, while the MBT602 includes thumbscrew adjusters with a 0.5 mm pitch. Unlike our 3-axis NanoMax™ and RollerBlock™ stages, these drives cannot be removed and replaced.

Easy Alignment of Accessories

The top platform features four 4-40 (M2), sixteen 6-32 (M3), and nine 8-32 (M4) mounting holes with two 3 mm wide central keyways in the top platform for rapid system reconfiguration while maintaining accessory alignment (see Figure 1.3). Click the blue info icon (![]() ) in Table 1.2 for the mounting hole layout.

) in Table 1.2 for the mounting hole layout.

The crossed pattern allows for changing the orientation of the stage for right- or left-handed use. A wide range of accessories is available to mount items such as microscope objectives, collimation packages, wave guides, fiber, and much more. If options are required for off-center mounting of components, the grooved top plate can be replaced with the RB13P1 adapter plate (sold at the bottom of this page), which has an array of 1/4"-20 (M6) and 8-32 (M4) mounting holes.

The MBT616D stage is also available preconfigured with a variety of fiber launch optomechanics.

| Multi-Axis Stage Accessories | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Fiber Mounts |

Fiber Rotators |

Waveguide Mounts |

Diode Mounts |

Fixed Mounts |

Kinematic Mounts |

Top Plates |

Extension Platforms |

Fiber Chucks |

Slide Holders |

Kinematic Platforms |

Adapter Plates |

Insights into Optical Fiber

Scroll down to read about:

- When does NA provide a good estimate of the fiber's acceptance angle?

- Why is MFD an important coupling parameter for single mode fibers?

- Does NA provide a good estimate of beam divergence from a single mode fiber?

Click here for more insights into lab practices and equipment.

When does NA provide a good estimate of the fiber's acceptance angle?

Click to Enlarge

Figure 192A Rays incident at angles ≤θmax will be captured by the cores of multimode fiber, since these rays experience total internal reflection at the interface between core and cladding.

Click to Enlarge

Figure 192B The behavior of the ray at the boundary between the core and cladding, which depends on their refractive indices, determines whether the ray incident on the end face is coupled into the core. The equation for NA can be found using geometry and the two equations noted at the top of this figure.

Numerical aperture (NA) provides a good estimate of the maximum acceptance angle for most multimode fibers, as shown in Figure 192A. This relationship should not be used for single mode fibers.

NA and Acceptance Angle

Incident light is modeled as rays to obtain the relationship between NA and the maximum acceptance angle (θmax ), which describes the fiber's ability to gather light from off-axis sources. The equation at the top of Figure 192A can be used to determine whether rays traced from different light sources will be coupled into the fiber's core.

Rays with an angle of incidence ≤θmax are totally internally reflected (TIR) at the boundary between the fiber's core and cladding. As these rays propagate down the fiber, they remain trapped in the core.

Rays with angles of incidence larger than θmax refract at the interface between core and cladding, and this light is eventually lost from the fiber.

Geometry Defines the Relationship

The relationship among NA, θmax , and the refractive indices of the core and cladding, ncore and nclad , respectively, can be found using the geometry diagrammed in Figure 192B. This geometry illustrates the most extreme conditions under which TIR will occur at the boundary between the core and cladding.

The equations at the top of Figure 192B are expressions of Snell's law and describe the rays' behavior at both interfaces. Note that the simplification sin(90°) = 1 has been used. Only the indices of the core and cladding limit the value of θmax .

Angles of Incidence and Fiber Modes

When the angle of incidence is ≤θmax , the incident light ray is coupled into one of the multimode fiber's guided modes. Generally speaking, the lower the angle of incidence, the lower the order of the excited fiber mode. Lower-order modes concentrate most of their intensity near the center of the core. The lowest order mode is excited by rays incident normally on the end face.

Single Mode Fibers are Different

In the case of single mode fibers, the ray model in Figure 192B is not useful, and the calculated NA (acceptance angle) does not equal the maximum angle of incidence or describe the fiber's light gathering ability.

Single mode fibers have only one guided mode, the lowest order mode, which is excited by rays with 0° angles of incidence. However, calculating the NA results in a nonzero value. The ray model also does not accurately predict the divergence angles of the light beams successfully coupled into and emitted from single mode fibers. The beam divergence occurs due to diffraction effects, which are not taken into account by the ray model but can be described using the wave optics model. The Gaussian beam propagation model can be used to calculate beam divergence with high accuracy.

Date of Last Edit: Jan. 20, 2020

Why is MFD an important coupling parameter for single mode fibers?

Click to Enlarge

Figure 192C For maximum coupling efficiency into single mode fibers, the light should be an on-axis Gaussian beam with its waist located at the fiber's end face, and the waist diameter should equal the MFD. The beam output by the fiber also resembles a Gaussian with these characteristics. In the case of single mode fibers, the ray optics model and NA are inadequate for determining coupling conditions. The mode intensity (I ) profile across the radius ( ρ ) is illustrated.

As light propagates down a single mode fiber, the beam maintains a cross sectional profile that is nearly Gaussian in shape. The mode field diameter (MFD) describes the width of this intensity profile. The better an incident beam matches this intensity profile, the larger the fraction of light coupled into the fiber. An incident Gaussian beam with a beam waist equal to the MFD can achieve particularly high coupling efficiency.

Using the MFD as the beam waist in the Gaussian beam propagation model can provide highly accurate incident beam parameters, as well as the output beam's divergence.

Determining Coupling Requirements

A benefit of optical fibers is that light carried by the fibers' guided mode(s) does not spread out radially and is minimally attenuated as it propagates. Coupling light into one of a fiber's guided modes requires matching the characteristics of the incident light to those of the mode. Light that is not coupled into a guided mode radiates out of the fiber and is lost. This light is said to leak out of the fiber.

Single mode fibers have one guided mode, and wave optics analysis reveals the mode to be described by a Bessel function. The amplitude profiles of Gaussian and Bessel functions closely resemble one another, which is convenient since using a Gaussian function as a substitute simplifies the modeling the fiber's mode while providing accurate results (Kowalevicz).

Figure 192C illustrates the single mode fiber's mode intensity cross section, which the incident light must match in order to couple into the guided mode. The intensity (I ) profile is a near-Gaussian function of radial distance ( ρ ). The MFD, which is constant along the fiber's length, is the width measured at an intensity equal to the product of e-2 and the peak intensity. The MFD encloses ~86% of the beam's power.

Since lasers emitting only the lowest-order transverse mode provide Gaussian beams, this laser light can be efficiently coupled into single mode fibers.

Coupling Light into the Single Mode Fiber

To efficiently couple light into the core of a single-mode fiber, the waist of the incident Gaussian beam should be located at the fiber's end face. The intensity profile of the beam's waist should overlap and match the characteristics of the mode intensity cross section. The required incident beam parameters can be calculated using the fiber's MFD with the Gaussian beam propagation model.

The coupling efficiency will be reduced if the beam waist is a different diameter than the MFD, the cross-sectional profile of the beam is distorted or shifted with respect to the modal spot at the end face, and / or if the light is not directed along the fiber's axis.

References

Kowalevicz A and Bucholtz F, "Beam Divergence from an SMF-28 Optical Fiber (NRL/MR/5650--06-8996)." Naval Research Laboratory, 2006.

Date of Last Edit: Feb. 28, 2020

Why is MFD an important coupling parameter for single mode fibers?

Significant error can result when the numerical aperture (NA) is used to estimate the cone of light emitted from, or that can be coupled into, a single mode fiber. A better estimate is obtained using the Gaussian beam propagation model to calculate the divergence angle. This model allows the divergence angle to be calculated for whatever beam spot size best suits the application.

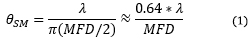

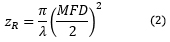

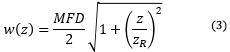

Since the mode field diameter (MFD) specified for single mode optical fibers encloses ~86% of the beam power, this definition of spot size is often appropriate when collimating light from and focusing light into a single mode fiber. In this case, to a first approximation and when measured in the far field,

, , |

is the divergence or acceptance angle (θSM ), in radians. This is half the full angular extent of the beam, it is wavelength  )

)

| Rayleigh Range: | ||

|

||

| Beam Radius at Distance z: | ||

|

||

|

Figure 194D These curves illustrate the consequence of using NA to calculate the divergence (θSM ) of light output from a single mode fiber. Significant error in beam spot diameter can be avoided by using the Gaussian beam propagation model. This plot models a beam from SM980-5.8-125. The values used for NA and MFD were 0.13 and 6.4 µm, respectively. The operating wavelength was 980 nm, and the Rayleigh range was 32.8 µm. |

||

Gaussian Beam Approach

Although a diverging cone of light is emitted from the end face of a single mode optical fiber, this light does not behave as multiple rays travelling at different angles to the fiber's axis.

Instead, this light resembles and can be modeled as a single Gaussian beam. The emitted light propagates similarly to a Gaussian beam since the guided fiber mode that carried the light has near-Gaussian characteristics.

The divergence angle of a Gaussian beam can differ substantially from the angle calculated by assuming the light behaves as rays. Using the ray model, the divergence angle would equal sin-1(NA). However, the relationship between NA and divergence angle is only valid for highly multimode fibers.

Figure 194D illustrates that using the NA to estimate the divergence angle can result in significant error. In this case, the divergence angle was needed for a point on the circle enclosing 86% of the beam's optical power. The intensity of a point on this circle is a factor of 1/e2 lower than the peak intensity.

Equations (2) and (3) were used to accurately model the divergence of the beam emitted from the single mode fiber's end face. The values used to complete the calculations, including the fiber's MFD, NA, and operating wavelength are given in Figure 194D's caption. This rate of beam divergence assumes a beam size defined by the 1/e2 radius, is nonlinear for distances z < zR, and is approximately linear in the far field (z >> zR).

The angles noted on the plot were calculated from each curve's respective slope. When the far field approximation given by Equation (1) is used, the calculated divergence angle is 0.098 radians (5.61°).

References

Kowalevicz A and Bucholtz F, "Beam Divergence from an SMF-28 Optical Fiber (NRL/MR/5650--06-8996)." Naval Research Laboratory, 2006.

Date of Last Edit: Feb. 28, 2020

Content improved by our readers!

| Posted Comments: | |

user

(posted 2019-08-14 16:46:12.71) I'd like to see some holes for dowel pins in the bottom of this unit so it could be positioned more accurately in an assembly than just with the clearance slots for the mounting screws. AManickavasagam

(posted 2019-08-16 03:58:15.0) Response from Arunthathi at Thorlabs: Thanks for your feedback. I have contacted you directly for extra details. Hoang Nguyen

(posted 2019-07-08 19:50:16.353) Hi,

One screw on my 3-axis stage MBT602 is stuck. Where can I buy a replacement for that screw? Thanks. AManickavasagam

(posted 2019-07-09 09:43:14.0) Response from Arunthathi at Thorlabs: Thanks for reaching out to us. We will contact you directly to get further details and send you a replacement screw. serjsmor

(posted 2014-12-08 04:02:11.393) And what if I want to move the stage in 3 axes : X,Y,Z ?

What product I should use ? serjsmor

(posted 2014-12-06 09:23:59.863) Is it possible to program the stage to move programatically ? msoulby

(posted 2014-12-08 03:45:26.0) Response from Mike at Thorlabs: Yes it is possible to program the stage, the most simply way would be to use the move sequencer in the APT User program, this is ideal if you only have 1 axis or stage to control and you can enter a series of moves that will be executed sequentially. Alternatively you can use a third party program such as Labview or Matlab we have contacted you directly with more information on using these applications with APT. msoulby

(posted 2014-12-08 04:21:21.0) Response from Mike at Thorlabs: Apologies the MBT stage is a manual stage and cannot be automated. If you would like a 3 axis automated stage then pleas consider our MAX300 range, specifically the MAX343/M 3-Axis NanoMax with Stepper Motors, please visit http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=2386 for more information. if you use this stage then our APT User program can be used to operate all of the axes of the stage and if you need to synchronise all three axes then a third party program such as Labview or Matlab can be used. user

(posted 2010-04-16 11:25:43.0) A response from Oli at Thorlabs to day: Unfortunately because of the mechanical design of the stage it cannot handle 1Kg in this orientation. However the stage can certainly be mounted like this to actuate light optics etc. day

(posted 2010-04-16 10:27:13.0) Is the load capacity still 1kg if the stage is mounted vertically (i.e. if the stage breadboard is vertical)? Can the stage be used in this orientation? klee

(posted 2009-08-06 16:33:30.0) A response from Ken at Thorlabs: It is a theoretical number. It is the smallest possible move a human hand can move the differential adjusters. iain

(posted 2009-08-04 22:29:44.0) Is the resolution of the MBT616 stage really 50 nm? Looking at the differential micrometers it looks more like 500 nm. Can you clarify how you define the resolution? |

Multi-Axis Stage Selection Guide

Click to Enlarge

Figure 83A In the above application, a 3-Axis NanoMax flexure stage is aligned in front of a 6-axis stage at the proper 112.5 mm deck height using an AMA554 Height Adapter.

3-Axis Stages

Thorlabs offers three different 3-Axis Stage variations: NanoMax flexure stages, MicroBlock compact flexure stages, and RollerBlock long-travel stages. Each stage features a 62.5 mm nominal deck height. Our NanoMax line of 3-axis stages offers built-in closed- and open-loop piezos as well as modular drive options that include stepper motors, differential drives, or additional piezos. The MicroBlock stages are available with differential micrometer drives or fine thread thumbscrews; these drives are not removable. Finally, our RollerBlock stage drivers can be switched out for any actuator that has a Ø3/8" (9.5 mm) mounting barrel.

4- and 5-Axis Stages

Our 4- and 5-axis stages are ideal for the static positioning of waveguides or complex optical elements with respect to our 3-axis or 6-axis high-performance alignment stages. Thorlabs' 5-axis stages have nominal heights of 62.5 mm or 112.5 mm. The AMA554 Height Adapter can be used to raise the deck height of the 3-axis or 4-axis stages to 112.5 mm for compatibility with our 5-axis MicroBlock or 6-Axis NanoMax Stages.

6-Axis Stages

Thorlabs' 6-Axis NanoMax Nanopositioners are ideal for complex, multi-axis positioning and have a nominal deck height of 112.5 mm. These stages offer a common point of rotation and a patented parallel flexure design that allows all actuators to be coupled directly to the base to minimize any unwanted motion in the system. Built-in closed- and open-loop piezo options are available. A selection of modular drive options allows any axis to be manual or motorized with the option for external piezos. Our units without included actuators are also available in right- or left-handed configurations. To increase the stage height of the 3-axis stages to 112.5 mm, we recommend our AMA554 Height Adapter, shown in Figure 83A.

A complete selection and comparison of our multi-axis stages is available below.

3-Axis Stages

| Item # | MAX313D | MAX312D | MAX311D | MAX383 | MAX381 | MAX303 | MAX302 | MAX301 | MBT602 | MBT616D | RB13M | RBL13D | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage Type | NanoMax Flexure Stages | MicroBlock Compact Flexure Stages |

RollerBlock Long Travel Stages | |||||||||||||||||

| Included Drives | DRV3 Differential Micrometers | DRV208 Stepper Motor Actuators | N/A | Fine Thread Thumbscrews | Differential Micrometers | 148-801ST Micrometer Drives |

DRV304 Differential Micrometers |

|||||||||||||

| Built-in Piezos | N/A | Open Loop |

Closed Loop | N/A | Closed Loop | N/A | Open Loop | Closed Loop | N/A | N/A | ||||||||||

| Travel (X, Y, Z) | 4 mm (0.16") | 13 mm (0.51") | ||||||||||||||||||

| Deck Height (Nominal) | 62.5 mm (2.46") | |||||||||||||||||||

| Optical Axis Height (Nominal) | 75 mm (2.95") | |||||||||||||||||||

| Load Capacity (Max) | 1 kg (2.2 lbs) | 4.4 kg (9.7 lbs) | ||||||||||||||||||

| Thermal Stability | 1 µm/°C | - | ||||||||||||||||||

| Weight | 1.00 kg (2.20 lbs) | 0.64 kg (1.40 lbs) | 0.59 kg (1.30 lbs) | |||||||||||||||||

4-Axis Stages

| Item # | MBT401D MBT401D/M |

MBT402D MBT402D/M |

|

|---|---|---|---|

| Stage Type | 4-Axis Thin-Profile MicroBlock Device Stage | 4-Axis Low-Profile MicroBlock Device Stage | |

| Included Drives | Differential Micrometers | ||

| Built-in Piezos | N/A | ||

| Travel | Horizontal Axis (Y)a | 13 mm (0.51") | |

| Vertical Axis (Z) | 6 mm (0.24") | ||

| Pitch (θy) | ±5° | ||

| Yaw (θz) | ±5° | ||

| Deck Height (Nominal) | 62.5 mm (2.46") | ||

| Optical Axis Height (Nominal) | 75 mm (2.95") | ||

| Load Capacity (Max) | 0.5 kg (1.1 lbs) | ||

5-Axis Stages

| Item # | MBT401D (MBT401D/M) or MBT402D (MBT402D/M) with MBT501 |

PY005 | |

|---|---|---|---|

| Stage Type | 5-Axis MicroBlock Stage System | Compact 5-Axis Stage | |

| Included Drives | Differential Micrometers | 100 TPI Actuators | |

| Built-in Piezos | N/A | ||

| Travel | Optical Axis (X) | 13 mm (0.51") | 3 mm (0.12") |

| Horizontal Axis (Y) | 13 mm (0.51") | 3 mm (0.12") | |

| Vertical Axis (Z) | 6 mm (0.24") | 3 mm (0.12") | |

| Pitch (θy) | ±5° | ±3.5° | |

| Yaw (θz) | ±5° | ±5° | |

| Deck Height (Nominal) | 112.5 mm (4.43") | 62.5 mm (2.46")a | |

| Optical Axis Height (Nominal) | 125 mm (4.92") | 75 mm (2.95")a | |

| Load Capacity (Max) | 0.5 kg (1.1 lbs) | 0.23 kg (0.5 lbs) | |

6-Axis Stages

| Item # | MAX601D MAX601D/M |

MAX602D MAX602D/M |

MAX603D MAX603D/M |

MAX681 MAX681/M |

MAX682 MAX682/M |

MAX683 MAX683/M |

MAX607 MAX607/M MAX607La MAX607L/Ma |

MAX608 MAX608/M MAX608La MAX608L/Ma |

MAX609 MAX609/M MAX609La MAX609L/Ma |

|

|---|---|---|---|---|---|---|---|---|---|---|

| Stage Type | 6-Axis NanoMax Flexure Stage | |||||||||

| Included Drives | DRV3 Differential Micrometers | DRV208 Stepper Motor Actuators | N/A | |||||||

| Built-in Piezos | N/A | Open Loop | Closed Loop | N/A | Open Loop | Closed Loop | N/A | Open Loop | Closed Loop | |

| Travel | X, Y, Z | 4 mm (0.16") | ||||||||

| θx, θy, θz | 6° | |||||||||

| Deck Height (Nominal) | 112.5 mm (4.43") | |||||||||

| Optical Axis Height (Nominal) | 125 mm (4.92") | |||||||||

| Load Capacity (Max) | 1.0 kg (2.2 lbs) | |||||||||

| Item # | MBT602(/M) | |

|---|---|---|

| Deck height | 62.5 mm (2.46") | |

| Optical Axis Height (Nominal) | 75 mm (2.95") | |

| Load Capacity (Max) | 1 kg (2.2 lbs) | |

| Drive Specifications | ||

| Travel Range | 4 mm (0.16") | |

| Resolution |

500 μm/rev | |

- Preconfigured with Thumbscrew Drives for Coarse Manual Adjustments

- Mounting Slots in Base Allow for Attachment to Breadboards and Optical Tables

- Flexure Design Circumvents Need for Grease and Enhances Long-Term Stability

- Ideal for Coarse Fiber Alignment for Fiber Launch Systems

Thorlabs' MicroBlock compact flexure stage with thumbscrew drives provides 4 mm (0.16") of coarse travel with 500 μm adjustment per revolution. This resolution and travel range make these stages ideal for optimizing the coupling efficiency in a fiber alignment or waveguide positioning system. Please note that unlike our selection of NanoMax™ and RollerBlock™ stages, we do not recommend removing the drives from the stage.

Imperial stages come with an MMP1 Top Plate, while metric stages come with an MMP1/M Top Plate. These mounting plates contain a central keyway that allows for easy and repeatable alignment of all of the accessories listed in the overview. If off-center or breadboard mounting is necessary, we also offer the RB13P1 Top Plate. More information on the MMP1(/M) and RB13P1(/M) Top Plates is available below.

This stage is also available preconfigured with a variety of fiber launch optomechanics for use in fiber launch systems.

| Item # | MBT616D(/M) | |

|---|---|---|

| Deck height | 62.5 mm (2.46") | |

| Optical Axis Height (Nominal) | 75 mm (2.95") | |

| Load Capacity (Max) | 1 kg (2.2 lbs) | |

| Drive Specifications | ||

| Travel Range | Coarse | 4 mm (0.16") |

| Fine | 300 μm | |

| Resolution | Coarse | 500 μm/rev |

| Fine | 50 μm/rev | |

- Preconfigured with Differential Micrometers for Coarse or Fine Manual Adjustments

- Mounting Slots in Base Allow for Attachment to Breadboards and Optical Tables

- Flexure Design Circumvents Need for Grease and Enhances Long-Term Stability

- Ideal for Use in Fiber Launch Systems

Thorlabs' MicroBlock compact flexure stage with differential micrometers provides 4 mm (0.16") of coarse travel with 500 µm adjustment per revolution, as well as 300 µm of fine travel with 50 µm travel per revolution. The travel range and resolution make these stages ideal for optimizing the coupling efficiency in a fiber alignment or waveguide positioning system. The graduations also allow for a clear reference point for absolute positioning within a system. Please note that unlike our selection of NanoMax™ and RollerBlock™ stages, we do not recommend removing the drives from the stage.

Imperial stages come with an MMP1 Top Plate, while metric stages come with an MMP1/M Top Plate. These mounting plates contain a central keyway that allows for easy and repeatable alignment of all of the accessories listed in the overview. If off-center or breadboard mounting is necessary, we also offer the RB13P1 Top Plate. More information on the MMP1(/M) and RB13P1(/M) Top Plates is available below.

This stage is also available preconfigured with a variety of fiber launch optomechanics for use in fiber launch systems.

Click to Enlarge

Figure 361A RB13P1 Top Plate Shown Replacing the MMP1 Crossed Groove Mounting Plate on an MAX311D Flexure Stage

- RB13P1 Adapter Plate for General Purpose Accessories and Components

- Array of Thirteen 1/4"-20 (M6) and Twelve 8-32 (M4) Tapped Mounting Holes

- MMP1 Standard 3-Axis Stage Top Plate (Included with All 3-Axis Stages)

- Two 3 mm Wide Central Keyways for Aligning Multi-Axis Stage Accessories

- Sixteen 6-32 (M3) Taps for Mounting Cleats

- Four 4-40 (M2) Taps

- Nine 8-32 (M4) Taps

The RB13P1(/M) Adapter Plate is designed as a replacement option for the standard MMP1(/M) grooved top plate sold with the stages above. Four counterbores that accept M3 screws allow it to be attached to the above stages. The 2.36" x 2.36" mounting surface is the same as the MMP1(/M) top plate that is included with the above stages. For complete details on the dimensions and tap locations of this top plate, please see the mechanical drawings in Table 361B.

The MMP1(/M) Top Plate is included with the stages sold above but can be purchased separately as well. This plate features two 3 mm wide central keyways in a crossed pattern to allow for rapid configuration while maintaining accessory alignment, making this plate ideal for fiber launch applications. This "crossed groove" design allows for the NanoMax stages to be used in a left- or right-handed configuration. The plate also contains an array of 4-40 (M2), 6-32 (M3), and 8-32 (M4) tapped mounting holes for securing and mounting various components. For complete details on the dimensions and tap locations of this plate, please see the mechanical drawings in Table 361B.

Products Home

Products Home

Zoom

Zoom

Compact Flexure Stages (MicroBlock)

Compact Flexure Stages (MicroBlock)