Manual Differential Drives, 25 mm and 50.8 mm Travel

- Compatible with a Wide Range of Stages

- Coarse Travel & High Resolution Adjuster in One Package

- Ø3/8" & Ø1/2" Mounting Barrels

- Ideal For OEM Applications

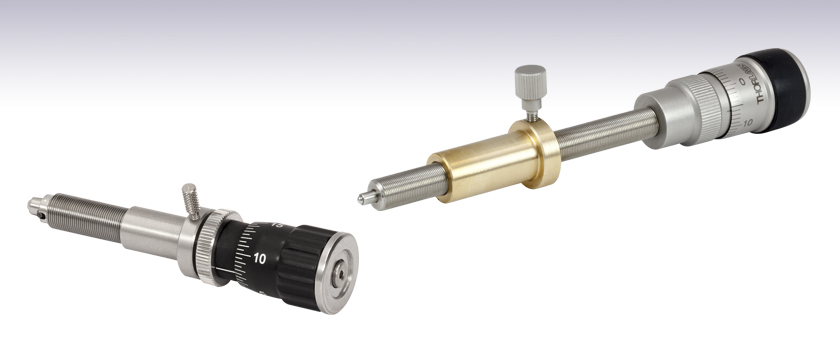

DM12

DRV8

Please Wait

| Specifications | ||

|---|---|---|

| Item # | DM12 | DRV8 |

| Coarse Adjustment Travel | 25 mm | 50.8 mm |

| Coarse Adjustment per Revolution | 0.5 mm | 0.5 mm |

| Fine Adjustment Travel | 250 µm | 300 µm |

| Fine Adjustment per Revolution | 25 µm with 0.5 µm Graduations | 0.05 mm with 1 µm Graduations |

Thorlabs offers a number of Manual Differential Drives for use with RollerBlock™ or TravelMax™ Stages. These differential drives in particular can be fitted to components with a standard Ø3/8" or Ø1/2" mounting barrel.

Fine Adjustment Knob Reattachment for Differential Adjusters

- Step 1: Fully remove the detached knob.

- Step 2: Apply pressure to the tip of the actuator.

- Step 3: While maintaining pressure, screw in the knob 2 to 3 threads.

- Step 4: Once threaded, remove pressure from Step 2 and continue to slowly screw in the knob. Please note that this should be done slowly and with little force. If too much force is applied, cross-threading may occur and may damage the threads.

Differential Adjuster Operation Mechanisms

A differential adjuster consists of four basic parts: outer body, coarse adjustment lock, inner spindle, and fine adjustment knob. Using the DM22 as an example, the video to the left demonstrates how these four parts come together to create a device that allows for coarse and fine adjustments. Also detailed are two different methods of mounting these actuators into an assembly.

Differential Adjuster Mechanisms

- Outer Body:

- Provides Coarse Adjustment

- Contains Internal Threads with a Pitch Smaller than the External Threads of the Inner Spindle

- Coarse Adjustment Lock:

- Prevents the Outer Body from Rotating; Locks Coarse Translation

- Enables Fine Adjustment

- Inner Spindle:

- Mounted within Outer Body

- Contacts the Moving Platform and will Translate with the Coarse Adjuster

- Contains External Threads with Greater Pitch than the Internal Threads of the Outer Body

- Fine Adjustment Knob:

- Internal and External Threads that Match the Inner Spindle and the Outer Body Threads

- Rotating the Knob Provides Inner Spindle Translation that is Equal to the Difference Between the Two Thread Pitches

| Posted Comments: | |

user

(posted 2019-10-25 10:47:46.153) What is the load capacity for DRV8? Is it same with DM12? cwright

(posted 2019-10-25 07:52:51.0) Hello and thank you for your question. The load capacity for the DRV8 should be 10 kg. user

(posted 2019-05-22 09:02:52.713) Hi. Does the locking screw prevent rotation of the differential fine adjuster, or only the macro adjuster? Thanks AManickavasagam

(posted 2019-05-23 06:15:05.0) Response from Arunthathi at Thorlabs: Thanks for your query. The locking screw fixes only the Macro/coarse adjuster position. This is to avoid cross coupling between the coarse and fine adjustment mechanism. georgy.onishchukov

(posted 2018-02-14 09:15:03.93) Dear Sir/Madam,

do you have any instruction about cleaning and especially lubricant to be used for smearing of the actuators?

We have problems that turning need too much force to be applied because of hardening of the grease in the thread.

Regards, Georgy

georgy.onishchukov@fau.de llamb

(posted 2018-02-20 09:13:46.0) Hello, thank you for contacting Thorlabs. You can clean the differential adjuster and its threads with acetone, and then apply Apiezon grease for lubrication. matthias.lange

(posted 2013-12-12 02:24:06.083) Hi,

what is the Load Capacity of the DM12 Micrometer Head?

Best regards,

Matthias jlow

(posted 2013-12-17 02:09:34.0) Response from Jeremy at Thorlabs: We recommend the load to be <15lbs for the DM12. |

- Standard Ø3/8" (Ø9.5 mm) Mounting Barrel

- High Resolution as Well as Coarse Adjustment in One Small Package

- Differential Adjustment Knob Graduated to Aid in Keeping Track of Position

- Coarse Adjustment: 0.5 mm per Revolution

- Fine Adjustment: 25 μm per Revolution

The DM12 Differential Adjuster uses two leadscrews; one pushes the center spindle forward with 400 μm per revolution, while the other pulls it back with 375 μm per revolution. The resultant total forward motion of the center spindle is just 25 μm for each complete revolution of the graduated knob. Each small graduation of the fine control knob is 0.5 μm; the smallest incremental move for the DM12 is approximately 0.5 μm. The coarse travel is lockable via a thumbscrew located on the Ø3/8" (Ø9.5 mm) mounting barrel, and when unlocked provides coarse adjustment of 0.5 mm per revolution. Also available is the DM10 1/2" Differential Adjuster. For more details on the operating mechanism of the DM12, please refer to the DM12 Operation tab.

If the fine adjustment knob on the DM12 is ever removed from the actuator body, it can be reattached. Please see the DM12 Knob Attachment tab for more details. Follow the reattachment instructions carefully so that the actuator functions properly.

- 50.8 mm (2") Travel

- Non-Rotating Tip

- Fine Resolution: 0.5 µm

- Ø1/2" (Ø12.7 mm) Interchangeable Brass Mounting Bushing

- Coarse Adjustment: 0.5 mm per Revolution

- Fine Adjustment: 50 µm per Revolution

The DRV8 Differential Drive has been designed for use with single-axis stages equipped with a Ø1/2" (Ø12.7 mm) actuator mounting clamp. The large-diameter differential drive actuator provides fine, ultra-smooth control over motion. The fine adjuster delivers 50 µm of travel per revolution with 1.0 µm graduations. The removable brass bushing allows this actuator to be used in any OEM application requiring 50.8 mm (2") of overall travel.

Products Home

Products Home

Zoom

Zoom Click to Enlarge

Click to Enlarge

Click to Enlarge

Click to Enlarge 25 mm & 50.8 mm Travel, Differential Drive

25 mm & 50.8 mm Travel, Differential Drive