Erbium-Doped SM and LMA Optical Fiber

- Erbium-Doped Fiber for Fiber Amplifiers and Lasers

- 1530 - 1610 nm Emission (C & L Bands)

- 980 nm and 1480 nm Pump Wavelengths

- Core-Pumped Single Mode or Large Mode Area Fibers Available

M12-980-125

ER30-4/125

Please Wait

| Item # | Type | Peak Core Absorption |

Pump Type |

MFD (at 1550 nm) |

Cladding Diameter |

|---|---|---|---|---|---|

| ER30-4/125 | SMa | 30.0 ± 3.0 dB/mc | Core | 6.5 ± 0.5 μm | 125 ± 2 μm |

| ER110-4/125 | 110.0 ± 10.0 dB/mc | ||||

| ER16-8/125 | LMAb | 16.0 ± 3.0 dB/mc | 9.5 ± 0.8 μm | ||

| ER80-8/125 | 80.0 ± 8.0 dB/mc | ||||

| M12-980-125 | SMa | 11.0 - 13.0 dB/md 16.0 - 20.0 dB/me |

5.7 - 6.6 µm | 125 ± 1 μm |

Features

- Er-Doped Optical Fiber for Emission in the 1530 - 1610 nm Wavelength Range

- Core-Pumped Single Mode and Large-Mode-Area Fibers Available

- Industry Standard Ø125 µm Cladding for Easy Handling, Splicing, and Termination

Thorlabs offers two lines of Erbium-doped active optical fibers. Liekki®* Er-doped fibers are single mode (SM) and large-mode-area (LMA) fibers for use with pump wavelengths of 980 nm or 1480 nm and emissions in the C and L telecommunications bands (1530 - 1565 nm or 1565 - 1625 nm, respectively). MetroGain Er-doped single mode fibers are designed for emission in L band and have high dopant concentrations for short device lengths.

We also offer Polarization-Maintaining Er-Doped Fibers.

*Liekki is a registered trademark of nLIGHT®.

| Active Fibers Selection Guide | |||

|---|---|---|---|

| Ytterbium-Doped SM and LMA | Ytterbium-Doped PM | Erbium-Doped SM and LMA | Erbium-Doped PM |

Liekki Erbium-Doped SM and LMA Active Fibers

| Item # | ER30-4/125 | ER110-4/125 | ER16-8/125 | ER80-8/125 |

|---|---|---|---|---|

| Peak Core Absorption @ 1530 nm | 30.0 ± 3.0 dB/m | 110.0 ± 10.0 dB/m | 16.0 ± 3.0 dB/m | 80.0 ± 8.0 dB/m |

| Mode Field Diameter (MFD) @ 1550 nm | 6.5 ± 0.5 μm | 6.5 ± 0.5 μm | 9.5 ± 0.8 μm | 9.5 ± 0.8 μm |

| Numerical Aperture (NA, Nominal) | 0.2 | 0.2 | 0.13 | 0.13 |

| Cut-Off Wavelength | 890 ± 90 nm | 890 ± 90 nm | 1250 ± 150 nm | 1250 ± 150 nm |

| Cladding Diameter | 125 ± 2 μm | |||

| Cladding Geometry | Round | |||

| Coating (Second Cladding) Diameter | 245 ± 15 μm | |||

| Coating Material | Dual-Coated High-Index Acrylate | |||

| Core Concentricity Error | ≤0.7 μm | |||

| Proof Test | ≥100 kpsi | |||

| Core Index | Proprietarya | |||

| Cladding Index | Proprietarya | |||

Fibercore MetroGain Erbium-Doped SM Active Fibers

| Item # | M12-980-125 |

|---|---|

| MFD (Nominal) | 5.7 - 6.6 µm at 1550 nm |

| Emission Wavelength | L-Band (1565 - 1625 nm) |

| Core Absorption @ 980 nm | 11.0 - 13.0 dB/m |

| Core Absorption @ 1531 nm | 16.0 - 20.0 dB/m |

| Core Numerical Aperture (NA, Nominal) | 0.21 - 0.24 |

| Cut-Off Wavelength | 900 - 970 nm |

| Cladding Diameter | 125 ± 1 μm |

| Cladding Geometry | Round |

| Coating Diameter (Nominal) | 245 ± 15 μm |

| Coating Material | Dual Acrylate |

| Background Loss | <20 dB/km |

| Core Concentricity Error | ≤0.5 μm |

| Proof Test | 1% (100 kpsi) |

| Core Index | Proprietarya |

| Cladding Index | Proprietarya |

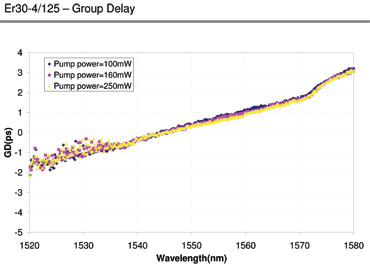

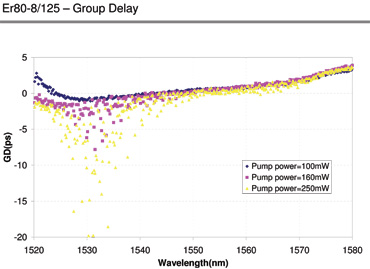

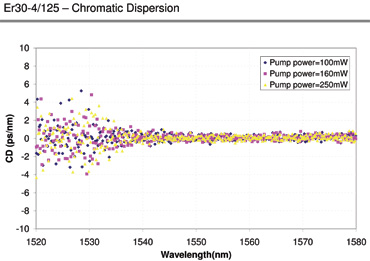

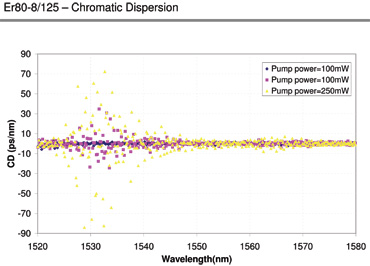

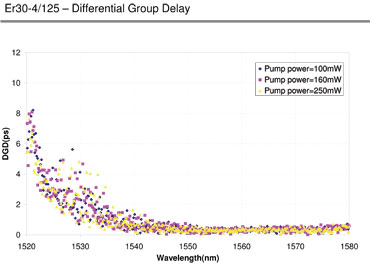

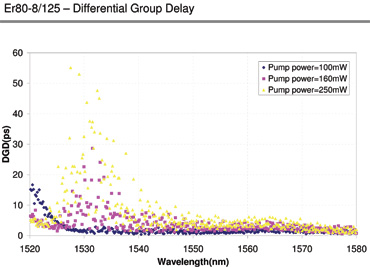

Testing of the group delay, chromatic dispersion, and differential group delay was performed for Er-doped fibers ER30-4/125 (approximately 5 m long) and ER80-8/125 (approximately 1 m long). The results are displayed below.

Group Delay

Below is the plot of group delay (GD) as a function of wavelength for three different pump powers for ER30-4/125 and ER80-8/125 Erbium-doped fiber. Group delay is the time required for information in a signal (i.e., any specific point on the modulation waveform) to travel the length of the optical path.

Chromatic Dispersion

Below is the plot of chromatic dispersion (CD) as a function of wavelength for three different pump powers for ER30-4/125 and ER80-8/125 Erbium-doped fibers. Chromatic dispersion is simply the local slope of the group delay versus wavelength graph.

Differential Group Delay

Below is the plot of differential group delay (DGD) as a function of wavelength for three different pump powers for ER30-4/125 and ER80-8/125 Erbium-doped fiber. Differential group delay is defined as the maximum group delay variation over all polarization states.

Active Optical Fiber Publications and Further Reading

As an emerging field of research, many advancements in doped fiber laser and amplifier construction are being made. The following publications contain information that may be helpful in the construction of fiber lasers and amplifiers.

2012

Bryce Samson, George Oulundsen, Adrian Carter, and Steven R. Bowman, "OPTICAL FIBER FABRICATION: Holmium-doped silica fiber designs extend fiber lasers beyond 2 µm," Laser Focus World, August 1, 2012

2011

Jianwu Ding, Bryce Samson, Adrian Carter, Chiachi Wang, Kanishka Tankala, "A Monolithic Thulium Doped Single Mode Fiber Laser with 1.5ns Pulsewidth and 8kW Peak Power," Proc. SPIE 7914, Fiber Lasers VIII: Technology, Systems, and Applications, 79140X (February 10, 2011); doi:10.1117/12.876867

2010

Timothy S. McComb, Pankaj Kadwani, R. Andrew Sims, Lawrence Shah, Christina C. C. Willis, Gavin Frith, Vikas Sudesh, Bryce Samson, Martin Richardson, "Amplification of Picosecond Pulses Generated in a Carbon Nanotube Modelocked Thulium Fiber Laser," in Lasers, Sources and Related Photonic Devices, OSA Technical Digest Series (CD) (Optical Society of America, 2010), paper AMB10.

G. Frith, A. Carter, B. Samson, J. Faroni, K Farley, K Tankala and G. E. Town, "Mitigation of photodegradation in 790nm-pumped Tm-doped fibers," Proc. SPIE 7580, Fiber Lasers VII: Technology, Systems, and Applications, 75800A (February 17, 2010); doi:10.1117/12.846230

Thomas Ehrenreich, Ryan Laveille, Imtiaz Majid, and Kanishka Tankala, Glen Rines, Peter Moulton "1-kW All-Glass Tm:fiber Laser," SPIE Photonics West 2010: LASE Presentation, Session 16: Late-Breaking News, January 29, 2010

2009

Gavin Frith, Adrian Carter, Bryce Samson, and Graham Town, "Design considerations for short-wavelength operation of 790-nm-pumped Tm-doped fibers," Appl. Opt. 48, 5072-5075 (2009)

S.D. Jackson, "The spectroscopic and energy transfer characteristics of the rare earth ions used fr silicate glass fibre lasers operating in the shortwave infrared," Laser & Photon. Rev., 3: 466–482. doi: 10.1002/lpor.200810058

Peter F. Moulton, Glen A. Rines, Evgueni V. Slobodtchikov, Kevin F. Wall, Gavin Frith, Bryce Samson, and Adrian L.G. Carter, "Tm-Doped Fiber Lasers: Fundamentals and Power Scaling," IEEE Journal of Selected Topics in quantum Electronics, Vol. 15, No. 1, Jan/Feb 2009

2006

Alexander Hemming, Shayne Bennetts, Nikita Simakov , John Haub, Adrian Carter, "Development of resonantly cladding-pumped holmium-doped fibre lasers," Proc. SPIE 8237, Fiber Lasers IX: Technology, Systems, and Applications, 82371J (February 9, 2012); doi:10.1117/12.909458

W. Torruellas, Y. Chen, B. McIntosh, J. Farroni, K. Tankala, S. Webster, D. Hagan, M. J. Soileau, M. Messerly, J. Dawson, "High peak power Ytterbium doped fiber amplifiers," Proc. SPIE 6102, Fiber Lasers III: Technology, Systems, and Applications, 61020N (February 23, 2006); doi:10.1117/12.646571

| Quick Links |

|---|

| Damage at the Air / Glass Interface |

| Intrinsic Damage Threshold |

| Preparation and Handling of Optical Fibers |

Laser-Induced Damage in Silica Optical Fibers

The following tutorial details damage mechanisms relevant to unterminated (bare) fiber, terminated optical fiber, and other fiber components from laser light sources. These mechanisms include damage that occurs at the air / glass interface (when free-space coupling or when using connectors) and in the optical fiber itself. A fiber component, such as a bare fiber, patch cable, or fused coupler, may have multiple potential avenues for damage (e.g., connectors, fiber end faces, and the device itself). The maximum power that a fiber can handle will always be limited by the lowest limit of any of these damage mechanisms.

While the damage threshold can be estimated using scaling relations and general rules, absolute damage thresholds in optical fibers are very application dependent and user specific. Users can use this guide to estimate a safe power level that minimizes the risk of damage. Following all appropriate preparation and handling guidelines, users should be able to operate a fiber component up to the specified maximum power level; if no maximum is specified for a component, users should abide by the "practical safe level" described below for safe operation of the component. Factors that can reduce power handling and cause damage to a fiber component include, but are not limited to, misalignment during fiber coupling, contamination of the fiber end face, or imperfections in the fiber itself. For further discussion about an optical fiber’s power handling abilities for a specific application, please contact Thorlabs’ Tech Support.

Click to Enlarge

Undamaged Fiber End

Click to Enlarge

Damaged Fiber End

Damage at the Air / Glass Interface

There are several potential damage mechanisms that can occur at the air / glass interface. Light is incident on this interface when free-space coupling or when two fibers are mated using optical connectors. High-intensity light can damage the end face leading to reduced power handling and permanent damage to the fiber. For fibers terminated with optical connectors where the connectors are fixed to the fiber ends using epoxy, the heat generated by high-intensity light can burn the epoxy and leave residues on the fiber facet directly in the beam path.

| Estimated Optical Power Densities on Air / Glass Interfacea | ||

|---|---|---|

| Type | Theoretical Damage Thresholdb | Practical Safe Levelc |

| CW (Average Power) |

~1 MW/cm2 | ~250 kW/cm2 |

| 10 ns Pulsed (Peak Power) |

~5 GW/cm2 | ~1 GW/cm2 |

Damage Mechanisms on the Bare Fiber End Face

Damage mechanisms on a fiber end face can be modeled similarly to bulk optics, and industry-standard damage thresholds for UV Fused Silica substrates can be applied to silica-based fiber. However, unlike bulk optics, the relevant surface areas and beam diameters involved at the air / glass interface of an optical fiber are very small, particularly for coupling into single mode (SM) fiber. therefore, for a given power density, the power incident on the fiber needs to be lower for a smaller beam diameter.

The table to the right lists two thresholds for optical power densities: a theoretical damage threshold and a "practical safe level". In general, the theoretical damage threshold represents the estimated maximum power density that can be incident on the fiber end face without risking damage with very good fiber end face and coupling conditions. The "practical safe level" power density represents minimal risk of fiber damage. Operating a fiber or component beyond the practical safe level is possible, but users must follow the appropriate handling instructions and verify performance at low powers prior to use.

Calculating the Effective Area for Single Mode Fibers

The effective area for single mode (SM) fiber is defined by the mode field diameter (MFD), which is the cross-sectional area through which light propagates in the fiber; this area includes the fiber core and also a portion of the cladding. To achieve good efficiency when coupling into a single mode fiber, the diameter of the input beam must match the MFD of the fiber.

As an example, SM400 single mode fiber has a mode field diameter (MFD) of ~Ø3 µm operating at 400 nm, while the MFD for SMF-28 Ultra single mode fiber operating at 1550 nm is Ø10.5 µm. The effective area for these fibers can be calculated as follows:

SM400 Fiber: Area = Pi x (MFD/2)2 = Pi x (1.5 µm)2 = 7.07 µm2 = 7.07 x 10-8 cm2

SMF-28 Ultra Fiber: Area = Pi x (MFD/2)2 = Pi x (5.25 µm)2 = 86.6 µm2 = 8.66 x 10-7 cm2

To estimate the power level that a fiber facet can handle, the power density is multiplied by the effective area. Please note that this calculation assumes a uniform intensity profile, but most laser beams exhibit a Gaussian-like shape within single mode fiber, resulting in a higher power density at the center of the beam compared to the edges. Therefore, these calculations will slightly overestimate the power corresponding to the damage threshold or the practical safe level. Using the estimated power densities assuming a CW light source, we can determine the corresponding power levels as:

SM400 Fiber: 7.07 x 10-8 cm2 x 1 MW/cm2 = 7.1 x 10-8 MW = 71 mW (Theoretical Damage Threshold)

7.07 x 10-8 cm2 x 250 kW/cm2 = 1.8 x 10-5 kW = 18 mW (Practical Safe Level)

SMF-28 Ultra Fiber: 8.66 x 10-7 cm2 x 1 MW/cm2 = 8.7 x 10-7 MW = 870 mW (Theoretical Damage Threshold)

8.66 x 10-7 cm2 x 250 kW/cm2 = 2.1 x 10-4 kW = 210 mW (Practical Safe Level)

Effective Area of Multimode Fibers

The effective area of a multimode (MM) fiber is defined by the core diameter, which is typically far larger than the MFD of an SM fiber. For optimal coupling, Thorlabs recommends focusing a beam to a spot roughly 70 - 80% of the core diameter. The larger effective area of MM fibers lowers the power density on the fiber end face, allowing higher optical powers (typically on the order of kilowatts) to be coupled into multimode fiber without damage.

Damage Mechanisms Related to Ferrule / Connector Termination

Click to Enlarge

Click to EnlargePlot showing approximate input power that can be incident on a single mode silica optical fiber with a termination. Each line shows the estimated power level due to a specific damage mechanism. The maximum power handling is limited by the lowest power level from all relevant damage mechanisms (indicated by a solid line).

Fibers terminated with optical connectors have additional power handling considerations. Fiber is typically terminated using epoxy to bond the fiber to a ceramic or steel ferrule. When light is coupled into the fiber through a connector, light that does not enter the core and propagate down the fiber is scattered into the outer layers of the fiber, into the ferrule, and the epoxy used to hold the fiber in the ferrule. If the light is intense enough, it can burn the epoxy, causing it to vaporize and deposit a residue on the face of the connector. This results in localized absorption sites on the fiber end face that reduce coupling efficiency and increase scattering, causing further damage.

For several reasons, epoxy-related damage is dependent on the wavelength. In general, light scatters more strongly at short wavelengths than at longer wavelengths. Misalignment when coupling is also more likely due to the small MFD of short-wavelength SM fiber that also produces more scattered light.

To minimize the risk of burning the epoxy, fiber connectors can be constructed to have an epoxy-free air gap between the optical fiber and ferrule near the fiber end face. Our high-power multimode fiber patch cables use connectors with this design feature.

Determining Power Handling with Multiple Damage Mechanisms

When fiber cables or components have multiple avenues for damage (e.g., fiber patch cables), the maximum power handling is always limited by the lowest damage threshold that is relevant to the fiber component. In general, this represents the highest input power that can be incident on the patch cable end face and not the coupled output power.

As an illustrative example, the graph to the right shows an estimate of the power handling limitations of a single mode fiber patch cable due to damage to the fiber end face and damage via an optical connector. The total input power handling of a terminated fiber at a given wavelength is limited by the lower of the two limitations at any given wavelength (indicated by the solid lines). A single mode fiber operating at around 488 nm is primarily limited by damage to the fiber end face (blue solid line), but fibers operating at 1550 nm are limited by damage to the optical connector (red solid line).

In the case of a multimode fiber, the effective mode area is defined by the core diameter, which is larger than the effective mode area for SM fiber. This results in a lower power density on the fiber end face and allows higher optical powers (on the order of kilowatts) to be coupled into the fiber without damage (not shown in graph). However, the damage limit of the ferrule / connector termination remains unchanged and as a result, the maximum power handling for a multimode fiber is limited by the ferrule and connector termination.

Please note that these are rough estimates of power levels where damage is very unlikely with proper handling and alignment procedures. It is worth noting that optical fibers are frequently used at power levels above those described here. However, these applications typically require expert users and testing at lower powers first to minimize risk of damage. Even still, optical fiber components should be considered a consumable lab supply if used at high power levels.

Intrinsic Damage Threshold

In addition to damage mechanisms at the air / glass interface, optical fibers also display power handling limitations due to damage mechanisms within the optical fiber itself. These limitations will affect all fiber components as they are intrinsic to the fiber itself. Two categories of damage within the fiber are damage from bend losses and damage from photodarkening.

Bend Losses

Bend losses occur when a fiber is bent to a point where light traveling in the core is incident on the core/cladding interface at an angle higher than the critical angle, making total internal reflection impossible. Under these circumstances, light escapes the fiber, often in a localized area. The light escaping the fiber typically has a high power density, which burns the fiber coating as well as any surrounding furcation tubing.

A special category of optical fiber, called double-clad fiber, can reduce the risk of bend-loss damage by allowing the fiber’s cladding (2nd layer) to also function as a waveguide in addition to the core. By making the critical angle of the cladding/coating interface higher than the critical angle of the core/clad interface, light that escapes the core is loosely confined within the cladding. It will then leak out over a distance of centimeters or meters instead of at one localized spot within the fiber, minimizing the risk of damage. Thorlabs manufactures and sells 0.22 NA double-clad multimode fiber, which boasts very high, megawatt range power handling.

Photodarkening

A second damage mechanism, called photodarkening or solarization, can occur in fibers used with ultraviolet or short-wavelength visible light, particularly those with germanium-doped cores. Fibers used at these wavelengths will experience increased attenuation over time. The mechanism that causes photodarkening is largely unknown, but several fiber designs have been developed to mitigate it. For example, fibers with a very low hydroxyl ion (OH) content have been found to resist photodarkening and using other dopants, such as fluorine, can also reduce photodarkening.

Even with the above strategies in place, all fibers eventually experience photodarkening when used with UV or short-wavelength light, and thus, fibers used at these wavelengths should be considered consumables.

Preparation and Handling of Optical Fibers

General Cleaning and Operation Guidelines

These general cleaning and operation guidelines are recommended for all fiber optic products. Users should still follow specific guidelines for an individual product as outlined in the support documentation or manual. Damage threshold calculations only apply when all appropriate cleaning and handling procedures are followed.

-

All light sources should be turned off prior to installing or integrating optical fibers (terminated or bare). This ensures that focused beams of light are not incident on fragile parts of the connector or fiber, which can possibly cause damage.

-

The power-handling capability of an optical fiber is directly linked to the quality of the fiber/connector end face. Always inspect the fiber end prior to connecting the fiber to an optical system. The fiber end face should be clean and clear of dirt and other contaminants that can cause scattering of coupled light. Bare fiber should be cleaved prior to use and users should inspect the fiber end to ensure a good quality cleave is achieved.

-

If an optical fiber is to be spliced into the optical system, users should first verify that the splice is of good quality at a low optical power prior to high-power use. Poor splice quality may increase light scattering at the splice interface, which can be a source of fiber damage.

-

Users should use low power when aligning the system and optimizing coupling; this minimizes exposure of other parts of the fiber (other than the core) to light. Damage from scattered light can occur if a high power beam is focused on the cladding, coating, or connector.

Tips for Using Fiber at Higher Optical Power

Optical fibers and fiber components should generally be operated within safe power level limits, but under ideal conditions (very good optical alignment and very clean optical end faces), the power handling of a fiber component may be increased. Users must verify the performance and stability of a fiber component within their system prior to increasing input or output power and follow all necessary safety and operation instructions. The tips below are useful suggestions when considering increasing optical power in an optical fiber or component.

-

Splicing a fiber component into a system using a fiber splicer can increase power handling as it minimizes possibility of air/fiber interface damage. Users should follow all appropriate guidelines to prepare and make a high-quality fiber splice. Poor splices can lead to scattering or regions of highly localized heat at the splice interface that can damage the fiber.

-

After connecting the fiber or component, the system should be tested and aligned using a light source at low power. The system power can be ramped up slowly to the desired output power while periodically verifying all components are properly aligned and that coupling efficiency is not changing with respect to optical launch power.

-

Bend losses that result from sharply bending a fiber can cause light to leak from the fiber in the stressed area. When operating at high power, the localized heating that can occur when a large amount of light escapes a small localized area (the stressed region) can damage the fiber. Avoid disturbing or accidently bending fibers during operation to minimize bend losses.

-

Users should always choose the appropriate optical fiber for a given application. For example, large-mode-area fibers are a good alternative to standard single mode fibers in high-power applications as they provide good beam quality with a larger MFD, decreasing the power density on the air/fiber interface.

-

Step-index silica single mode fibers are normally not used for ultraviolet light or high-peak-power pulsed applications due to the high spatial power densities associated with these applications.

| Posted Comments: | |

lisa tonnelier

(posted 2023-11-28 15:39:10.927) Hello,

What are the following characteristics of the ER30-4/125 fibre?

effective absorption cross-section at the pump wavelength (980nm)

effective emission cross-section at the signal wavelength (1550 nm)

effective absorption cross-section at signal wavelength (1550nm)

-Level 2 lifetime

-Density of erbium ions in silica ksosnowski

(posted 2023-11-30 10:35:35.0) Thanks for reaching out to Thorlabs. The ER30-4/125 Level 2 lifetime is 9 ms. The density of erbium ions is about 2.5E+25 ions/m^3. I have reached out directly to share further details on these emission and absorption cross-sections as well. theo philippe kagan

(posted 2023-11-28 15:30:42.743) Hello,

What are the following characteristics of the ER30-4/125 fibre?

effective absorption cross-section at the pump wavelength (980nm)

effective emission cross-section at the signal wavelength (1550 nm)

effective absorption cross-section at signal wavelength (1550nm)

-Level 2 lifetime

-Density of erbium ions in silica ksosnowski

(posted 2023-11-30 10:37:13.0) Thanks for reaching out to Thorlabs. The ER30-4/125 Level 2 lifetime is 9 ms. The density of erbium ions is about 2.5E+25 ions/m^3. I have reached out directly to share further details on these emission and absorption cross-sections as well. muhammad abdullah

(posted 2023-05-18 01:50:43.84) Dear Sir: Can you please provide the dataset file for the emission and absorption cross section against wavelength. Alex Pa

(posted 2023-02-08 07:21:26.243) Hello,

I want to select a proper fiber for EDFA, low ASE is critical in my application. Should I expect a difference in ASE between ER16-8 and ER80-8 if I the length I choose for each one of them provides the same amplification?

Thank you cdolbashian

(posted 2023-04-03 12:29:55.0) Thank you for reaching out to us Alex. While there is likely a length of one fiber which would generate similar amplification as the other, we do not have detailed doping information for these fibers such that we could provide this data for you. I have reached out to you to discuss this. Hamed Ahmad

(posted 2023-01-15 18:08:25.307) Hello Thorlabs. Is there any information for erbium concentration, doping model (rectangular or Gaussian), doping radius, fiber NA and core radius of ER80-8/125? jgreschler

(posted 2023-01-17 09:09:57.0) Thank you for reaching out to Thorlabs. Additional data and specs can be requested by contacting techsupport@thorlabs.com. I have reached out to you directly to discuss these details. Alexander Block

(posted 2022-09-13 13:41:22.207) I think the Attenuation spec is listed falsely as 8 +- 8 dB, instead of 80+-8 in some places ppestre

(posted 2022-09-16 02:58:52.0) Thank you for your feedback! The spec has been corrected. Amir Tehra

(posted 2022-07-12 15:49:26.067) How much is the lifetime (tao) for ER110? jgreschler

(posted 2022-08-02 02:29:25.0) Thank you for reaching out to Thorlabs. The emission lifetime of the spontaneous emission in the erbium doped fibers is roughly 9 ms. Jun Park

(posted 2021-09-01 09:39:57.407) For three of below products

ER30-4/125

ER110-4/125

M5-980-125

I want to gain 23dB.

It will be pumped by 980 nm or 1480nm.

1. What pump power level should I need for each products...?

2. What length should I need for each products...?

3. Could you recommend proper LD model...?

Thanks. cdolbashian

(posted 2021-09-10 11:04:00.0) Thank you for contacting us at Thorlabs! It seems like your performance requirements and are significantly application dependent. I have contacted you directly regarding your inquiries. HA CHANGKYUN

(posted 2021-07-02 18:03:40.58) Hello Thorlabs. Is there any information for erbium concentration in ppm unit? YLohia

(posted 2021-07-02 09:37:51.0) Hello, the estimated density of erbium ions in the M5-980-125 is typically 7.85 x 10^24 ions/m^3 or around 4400 ppm. user

(posted 2021-03-03 19:53:38.413) Hi!

Will you be able to suggest pump power required (1480 nm pumping) and optimum active fiber length for ER30-4/125, for achieving a gain of 20 dB, for an i/p signal (1530-1560 nms) power level of 0 dBm? many thanks. asundararaj

(posted 2021-03-04 01:44:11.0) Thank you for contacting Thorlabs. I have contacted you directly about your application. Muhammad Ghawas

(posted 2019-08-20 03:29:00.087) Hi Thorlabs,

I need the absorption and emission cross section curves for the ER80-8/125. Cooperation in this regards would be highly appreciated. YLohia

(posted 2019-08-20 10:22:44.0) Hello, I have reached out to you directly with this information. Robert Baker

(posted 2019-07-15 18:19:00.95) Hi Thorlabs,

The dispersion data are nice but it would help a lot of ultrafast fiber laser people if you quoted your dispersion for every fiber in standard units.

So from the graph I can easily calculate that it's 1 ps in approx 10 nm which over 5 meters gives

1 ps/ 10 nm / 0.005 km = 20 ps/nm-km

This is approximately 2.6e-26 s^2/m.

If you quote values in this format for your gain fibers, and especially if you quote higher order dispersion data, ultrafast fiber laser people will buy more from Thorlabs merely because they can simulate before they buy and a lot of the product data is proprietary. For instance, I'm using some Er-30 right now and I tried to simulate the dispersion to higher order but since the index data are proprietary I can't even do that.

There are many ways to get to the same dispersion values so I think it makes sense for me the customer to get full dispersion curves measured or at least simulated by suppliers to higher order. This way I know what I'm buying in terms that the scientific ultrafast community is used to. YLohia

(posted 2019-08-19 09:34:58.0) Hello Robert, thank you for your feedback. The nominal GVD for the ER30-4/125 is 2.30E-26 s^2/m. We will look into providing this data on the website. 117011

(posted 2018-01-09 17:41:56.173) I'm interested in dispersion of ER16-8/125.

can you provide dispersion data of it? tfrisch

(posted 2018-03-20 04:30:56.0) Hello, thank you for contacting Thorlabs. We can email you simulated dispersion data. till.walbaum

(posted 2017-03-30 09:25:23.063) For the dispersion data given for Er80-8 and Er110-4, what fiber lengths were measured? Can you provide dispersion data in terms of GVD instead of GD, e.g. ps/(nm km) or ps^2/m? tfrisch

(posted 2017-04-18 03:53:30.0) Hello, thank you for contacting Thorlabs. The data listed on our webpage was taken with 5m of Er30-4/125 and 1m of Er80-8/125. I see that you have already contacted Tech Support for further details. xgsun

(posted 2016-06-13 07:48:49.787) what is the absorption ~1450 to 1480 for ER80-8/125? can you send me the absorption spectrum?

Thank besembeson

(posted 2016-06-14 03:44:17.0) Response from Bweh at Thorlabs USA: On the product page, we do provide the peak absorption at 1530nm and the normalized absorption spectrum that can be used to estimate the absorption at your wavelengths of interest. scottie730318

(posted 2015-05-13 23:25:15.49) Dear Sir:

we have purchased the Er-doped gain fiber (LIEKKI™ Er80-8/125). Could you provide us the splicing parameters which are used to splice the "Er80-8/125 and SMF-28" and "Er80-8/125 and Hi-1060"?

Our fusion splicer is the model: FSM-60s from Fujikura.

Thank you very much

Best Wishes rwalz

(posted 2015-07-30 04:16:18.0) Hello. We do not have splicing profiles or recommendations for the various fiber fusion devices. The fiber physical specifications are available on the "Specs" tab on the product page. taoliu

(posted 2013-12-12 08:24:26.63) Hi, I am interrested in the absorption curve (in dB/m) and the emission curve (if possible) for Er30-4 and Er80-4 doped fibers. pbui

(posted 2013-12-31 11:50:41.0) Response from Phong at Thorlabs: We will contact you directly to provide the emission/absorption curves for the Er30-4/125 and Er80-4/125 fibers. skyzeus

(posted 2013-12-02 21:33:47.323) Hi, I am interrested in the GVD curve for Er80-4 and Er80-8 doped fibers. I am also interrested in the group delay curves of these fibers. If you can provide this information in text format, it would be the best, but I can also work with pdfs. Thanks tcohen

(posted 2013-12-05 02:58:24.0) Response from Tim at Thorlabs. Thanks for your feedback. We’ve emailed you with dispersion data. maxime.hardy

(posted 2013-06-27 15:07:27.05) Hi, I am interrested in the absorption curve (in dB/m) and the emission curve (if possible) for Er30-4 and Er80-4 doped fibers.

I am also interrested in the group delay curves of these fibers.

If you can provide this information in text format, it would be the best, but I can also work with pdfs.

Thanks pbui

(posted 2013-07-30 09:54:00.0) Response from Phong at Thorlabs: Thank you for your interest. We will contact you directly regarding the curves for the Er30-4/125 and Er80-4/125 fibers. fstrohkendl

(posted 2013-02-11 17:58:35.19) From your catalogue"Large-Mode-Area (LMA) Double Cladding Erbium fibers are also available on request. These highly doped fibers have a core size from 20 to 30 µm with a 125 µm cladding."

Please provide info on LMA Er doped fibers.

Thank you. tcohen

(posted 2013-02-21 15:06:00.0) Response from Tim at Thorlabs: Thank you very much for your inquiry. I have sent you documentation directly for your review. Laurie

(posted 2008-05-07 08:21:00.0) Response from Laurie at Thorlabs to czakon: Thank you for your email. You should have received the absorption information requested from Fatih, a member of our our technical support staff. In addition, we will be posting this information on the website shortly so that it is more readily available. We apologize for teh extra step you had to go through to obtain this information. czakon

(posted 2008-04-18 18:47:50.0) Hello,

I am interested in the absorption and emission curves of er80-4/125. I noticed they used to be in the faqs section of the site and i can no longer find this information. could you please send me the information n PDF format?

Thanks!

Nicole |

| Key Features | |

|---|---|

| ER30-4/125 | Extremely high, >50% conversion efficiency in the L band |

| ER110-4/125 | Extremely high doping concentration for short device length and reduced nonlinearity |

| ER16-8/125 | Good spliceability, power conversion efficiency, and spectral reproducibility |

| ER80-8/125 | For 980 nm pumps with emission at 1550 nm. Large core and good spliceability. |

- For Emission from 1530 to 1610 nm with 980 nm and 1480 nm Pump Sources

- Geometric Properties Provide Very Low Birefringence and Excellent Splice Characteristics

- Typical Splice Loss to SM Fiber of Pump Laser: <0.1 dB

- Typical Splice Loss to SMF-28e+ Fiber: <0.15 dB

Applications

- C- and L-Band DWDM, Metro, CATV, and PON

- ASE Sources

- CW and Pulsed Lasers and Amplifiers

Liekki highly doped erbium fibers are suitable for fiber lasers and amplifiers operating in the 1530 to 1610 nm wavelength region (C and L bands). These fibers cover broad application fields ranging from telecommunication amplifiers (EDFAs) to high-power PON/CATV boosters and ultra-short pulse amplifiers used in instrumentation, industrial, and medical applications. These highly doped fibers have a standard Ø125 µm cladding.

| Item # | Type | Peak Core Absorption at 1530 nm |

Mode Field Diameter at 1550 nm |

Cladding Diameter |

Coating Diameter |

Core NA (Nominal) |

Cut-Off Wavelength |

Core Index |

Cladding Index |

|---|---|---|---|---|---|---|---|---|---|

| ER30-4/125 | Single Mode | 30.0 ± 3.0 dB/m | 6.5 ± 0.5 µm | 125 ± 2 µm | 245 ± 15 µm | 0.2 | 890 ± 90 nm | Proprietarya | Proprietarya |

| ER110-4/125 | 110.0 ± 10.0 dB/m | ||||||||

| ER16-8/125 | Large Mode Area | 16.0 ± 3.0 dB/m | 9.5 ± 0.8 µm | 0.13 | 1250 ± 150 nm | ||||

| ER80-8/125 | 80.0 ± 8.0 dB/m |

- For 980 nm Pump Sources with Emission in the L Band (1565 - 1625 nm)

- High Absorption for Short Gain Sections or Laser Cavities

Applications

- L-Band Fiber Amplifiers

- ASE Sources

MetroGain Erbium-doped fiber M12-980-125 is optimized for emission in the L telecommunications band with a 980 nm pump source. Its high absorption allows for shorter active fiber lengths compared to conventional Er-doped fibers emitting in the L band.

These fibers give good modal overlap of the pump with the doped region of the fiber while still maintaining excellent splice characteristics. The high absorption of MetroGain fibers makes them an ideal choice for fiber lasers and ASE sources. Very short cavity lengths for fiber lasers can be realized, which minimizes pulse distortion.

| Item # | Type | Emission Wavelength |

Absorption | MFD @ 1550 nm (Nominal) |

Cladding Diameter |

Coating Diameter (Nominal) |

Core NA | Cut-Off Wavelength |

Core/Cladding Index |

|---|---|---|---|---|---|---|---|---|---|

| M12-980-125 | Single Mode | L-Band | 11.0 - 13.0 dB/m @ 980 nm 16.0 - 20.0 dB/m @ 1531 nm |

5.7 - 6.6 µm | 125 ± 1 µm | 245 ± 15 µm | 0.21 - 0.24 | 900 - 970 nm | Proprietarya |

Products Home

Products Home

Zoom

Zoom

Er-Doped SM and LMA Fiber

Er-Doped SM and LMA Fiber