Optical Adhesives

- Optical-Grade Epoxy

- Optically Clear Double-Sided Adhesive Tape

FH5313PK

Optical-Grade Epoxy

OCA8146-3

20 Sheets per Pack

Please Wait

Thorlabs offers the Optical-Grade Epoxy and Optically Clear Double-Sided Adhesive Tape. Thorlabs also carries standard epoxies and adhesives.

| Summary of Lamination Process | ||

|---|---|---|

| Pre-Bake in Dry, Clean Oven (Plastic Substrate Only) |

Temperature | 85 °C |

| Duration | 2 - 5 Hours | |

| Sample Preparation | Environment | Class 10K Cleanroom or Better |

| Temperature | ≥24 °C | |

| Tools | Wipes, Air Ionizer Gun, Isopropyl Alcohol | |

| Lamination | Environment | Class 10K Cleanroom or Better |

| Temperature | ≥24 °C | |

| Tools | Vacuum Table or Polyester Tape, Roller | |

| Autoclave | Temperature | 30 - 60 °C |

| Pressure | 70 - 100 PSI | |

| Duration | 20 - 60 Minutes | |

Recommended Tools and Environmental Conditions for

OCA8146-2 & OCA8146-3

- Class 10K Cleanroom or Better

- Vacuum Table or Glass Table Work Station

- Clean Rubber Roller, Autoclave, and Polyester Tape

- Wipes without Free Floating Fibers, Air Ionizer Gun, and Isopropyl Alcohol

3M's Optically Clear Double-Sided Adhesive Tape (OCA) offers exceptional bonding for smooth, transparent substrates such as glass or plastic. Plastic substrates (e.g., PC and PMMA) absorb moisture and outgas when exposed to high temperature or humidity. This causes bubbles to appear in laminated parts and reduces the optical transparency. To avoid this potential problem, plastics can be baked at 85 °C for 2 - 5 hours in order to drive the moisture out of the substrate. The table to the right gives a summary of the steps in the lamination process detailed below.

Lamination Process

Substrate Preparation

1) If using a plastic substrate, bake it at 85 °C for 2 - 5 hours. Before laminating a substrate first clean all surfaces to be bonded together. Use a soft, dust-free cloth or wipe (such as Thorlabs' CP-100 Premium Optical Cleaning Pads) and isopropyl alcohol to clean the substrate surfaces. Inspect the surfaces to ensure that they are clean, dry, and free of dust and other contaminants.

2) Secure the first substrate to a flat, clean surface with the cleaned side up. Ideally the substrate will be secured with a vacuum table, but in the absence of such, polyester masking tape can be used to secure the substrate.

Lamination

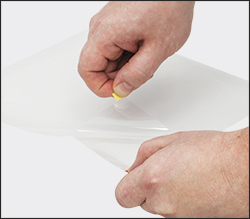

3) Remove the first liner from the OCA film. The OCAs come with three tape handles on each sheet to aid the user in removing the film without touching the OCA (see image to the right).

4) Align the OCA with the substrate and use the rubber roller to adhere the OCA onto the secured substrate. Be sure to squeeze out all the air to avoid air pockets in the lamination.

5) Remove the back side liner and align the second substrate (cleaned surface facing the OCA). Roll down on the second substrate to squeeze all the air from the laminated surfaces.

Autoclave

6) An autoclave is typically used as the final step in the lamination process. It uses heat and pressure to squeeze out any remaining air from the laminated surfaces. For the purpose of lamination, a dry autoclave must be used. See the table above for the autoclave settings. After the autoclave is complete, the lamination process if finished.

| Posted Comments: | |

Paul Pulaski

(posted 2024-01-24 12:01:42.12) Hello, The optical epoxy FH5313PK works very well, however there are tiny bubbles that form when you mix the two parts together. How can one get rid of the tiny bubbles after mixing and before using?

Thank you,

Paul jpolaris

(posted 2024-01-26 06:08:19.0) Thank you for contacting Thorlabs. The best way to prevent bubbles is to mix thoroughly at a medium-slow speed. Mixing too fast can bring air into the mixture, leading to bubbles. It can be tedious, and will take some practice, but proper mixing technique can prevent bubbles. Felix Dreisow

(posted 2021-09-01 09:15:37.84) We use the sheets as raw material and cut them into single parts. However, we just have the pull tabs on one edge. Can you supply the red sticker as material? YLohia

(posted 2021-09-01 10:45:28.0) Hello, thank you for contacting Thorlabs. We have reached out to you directly to discuss the feasibility of offering this. roberto_duran

(posted 2017-08-11 18:32:25.467) It is possible to get it customized to different cut size?

We needed with the size 72.90 X 129.60 mm nbayconich

(posted 2017-08-28 05:00:14.0) Thank you for contacting Thorlabs. Unfortunately we cannot offer custom cut optically clear adhesive tape at the moment. This tape can be easily cut with scissors. I will reach out to you directly. g.wyen

(posted 2016-11-29 14:06:55.4) Hi,

is there a way to buy the OCA film in custom cut size ? And is it possible to get a sample of the 3 mils version ? We bought the 2 mils version but it is impossible to get it off once it is attached (cutting wire is too thick) , also the 2mils version didn't work perfectly when ink steps were present.

thanks in advance

Gerrit Wyen tfrisch

(posted 2016-12-15 12:52:50.0) Hello, I will contact you directly about your application. vera

(posted 2015-11-06 09:09:25.95) Dear Sir,

I am looking for optical clean transter adhesive.

Do you have such type of material?

How much it costs?

Thank you very much in advance.

Kind regards.

Vera besembeson

(posted 2015-11-18 06:28:06.0) Response from Bweh at Thorlabs USA: We don't have these as stock items at the moment. I will follow-up with you to provide this optical clear transfer adhesive as a special item. Aayyad

(posted 2015-09-08 01:06:28.12) Hi i would like to know what is the best technique or solvent for removing this adhesive? For refurbishing purposes etc besembeson

(posted 2015-09-30 09:34:31.0) Response from Bweh at Thorlabs USA: Depending on what the adhesive was applied to, WD-40 will dissolve the residue on any glass surface. If it was a plastic or metal the WD-40 could potentially cause discoloration. nostalgicracing

(posted 2014-07-19 11:59:49.68) I am interesting to trying your Optically Clear Double-Sided Adhesive Sheets.

Can I get a sample sheet of this material first to see if it works for our application.

We want to use your product to mount signs to the inside of glass windows.

Please contact me if you have any other questions.

Jim Hill

Nostalgic Racing Decals Inc.

637 Sedgewick Way

Palm Harbor, Florida 34683

(727)455-6141 jlow

(posted 2014-08-01 11:18:50.0) Response from Jeremy at Thorlabs: We can send you samples for this. You can also request samples by contacting us at techsupport@thorlabs.com. |

Click to Enlarge

Click for Raw Data

Total transmission through FH5313PK Optical-Grade Epoxy. The shaded region highlights the wavelengths for which the transmission is >90%.

- Ideal for Bonding Optical Substrates

- >90% Optical Transmission from 360 nm - 2100 nm

- Refractive Index: 1.66

- Continuous Operation at Temperatures up to 200 °F

- Tensile Strength: 7800 psi

- Flexure Strength: 14,800 psi

- Low Outgassing

The FH5313PK Optical-Grade Epoxy is ideal for bonding optical substrates, potting, and encapsulation. It has >90% transmission from 360 nm - 2100 nm as well as good chemical resistance, mechanical strength, and thermal stability. Its low outgassing enables use in space-borne systems. This two-component epoxy has a cure time of 48 hours at room temperature; the cure time can be accelerated to 5 hours at 122 °F (50 °C). The epoxy is packaged in two separate bags with a net weight of 6 grams.

Dangerous Goods

The FH5313PK epoxy is classified as dangerous goods in some countries. Depending on the delivery location, this item may need to be shipped separately from the rest of your order (and possibly with a different carrier) at an additional charge. Please contact our sales department if there are questions or concerns when placing an order for this item.

Shelf Life

When stored at room temperature, the FH5313PK epoxy has a shelf life of 365 days. The shelf life is extended to 12 years when stored at 12 °C. This time frame begins on the date the epoxy was packaged at the manufacturer. Upon receipt by the end user, Thorlabs guarantees that the remaining shelf life will be at least 3 months.

- 3M Optically Clear Double-Sided Acrylic Adhesive Tape

- >99% Transmission and <1% Haze Level

- Alternative to UV-Cured Optical Adhesives

- Provides a High Bond Strength to a Variety of Surfaces

- Sold in a Pack of 20 Sheets

3M's Optically Clear Double-Sided Tape provides high cohesive and peel strength to reliably bond many transparent substrates or optical devices and is an alternative to our UV-curing optical adhesive. This tape is ideal for bonding optical films together, such as a lenslet foil to a polarizer foil or glass substrate. Additionally, it can be used with bare Indium Tin Oxide (ITO) surfaces. Two thicknesses are available, 2 mils (0.050 mm) and 3 mils (0.075 mm); the thinner sheet offers slightly better transmission where as the thicker sheet is less likely to tear or break during application.

When properly applied, it can resist splashes from acetone, isopropyl alcohol, and cleaners. Furthermore, immersion in water has no measurable effect on the strength and durability of the tape’s bond. For maximum bond strength, the surfaces of the mating pieces should be thoroughly cleaned and dried.

This optically clear, double-sided tape offers high temperature resistance as well as long-term durability without yellowing, delaminating, or degrading. A pressure-sensitive rotary cutter may be used to cut the sheets if necessary. See the Tape Bonding tab for detailed instructions on how to use this tape.

Click to Enlarge

Total transmission through one sheet of OCA8146-3 optically clear tape. The shaded region highlights the designed wavelength range for the tape. The transmission for the OCA8146-2 will be similar to this plot, but with slightly better performance.

| Item # | OCA8146-2 | OCA8146-3 |

|---|---|---|

| Wavelength Range | 400 - 780 nm | |

| Material | Acrylic | |

| Sheet Size | 250 mm × 210 mm (9.84" × 8.27") |

250 mm × 195 mm (9.84" × 7.68") |

| Sheet Thickness | 2 mils (0.050 mm) | 3 mils (0.075 mm) |

| Transmissiona | >99% | |

| Haze Levelb | <1% | |

| Refractive Index @ 589.3 nm | 1.4740 ± 0.0005 @ 25 °C | |

| Dielectric Constant | 5.14 @ 1 kHz | |

| Peel Adhesion to Glassc | 54 N/100 mm | 58 N/100 mm |

| Short Term Temperature | 177 °C (Max) | |

| Long Term Temperature | -40 to 85 °C | |

Products Home

Products Home

Zoom

Zoom

Optical Adhesives

Optical Adhesives