Ø1.5" Post V-Clamp Mounts

- Ideal for Mounting Tube Lasers on Our Ø1.5" Stainless Steel Posts

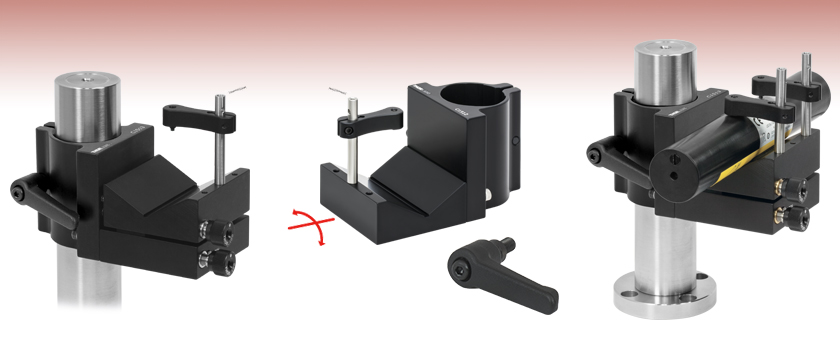

PM4

Clamping Arm

(One Included with Each Mount)

C1513

Kinematic with ±2.2° Pitch & ±2.7° Yaw

C1512

±10° Manual

Pitch Adjustment

Application Idea

C15QR

Quick-Release Handle

An extra PM4 clamping arm can be added for increased stability.

Please Wait

| Ø1.5" Post Accessories |

|---|

| Construction Accessories |

| V-Mounts |

| Mounting Plates |

| Brackets / Platforms |

| Mirror Mounts |

Thorlabs' Post V-Clamp Mounts are designed to fasten HeNe Lasers to our Ø1.5" Posts using a clamping mechanism that is actuated with the attached handle. The V-clamp mount provides two lines of contact along the bottom, and the included PM4(/M) Clamping Arm provides a third point of contact at the top. They are compatible with cylinders ranging in size from Ø0.28" to Ø2.04" (Ø6.5 mm to Ø51.9 mm), and are fabricated from black-anodized aluminum.

The C1512(/M) Post V-Clamp Mount provides coarse pitch adjustment of ±10°. In contrast, the C1513(/M) Kinematic V-Clamp Mount includes two knobs that provide ±2.2° of pitch and ±2.7° yaw control. Three 6-32 (M4) taps along the outer edge of each the V-clamp provide flexible mounting locations for the included clamping arm. For additional stability, extra clamping arms may be purchased below.

These clamps feature a quick-release handle for securing the clamp to a post. The handle contains a 1/4"-20 (M6) threaded stud that engages the part by simply rotating the handle. An internal mechanism allows the handle's rotational position to be adjusted without actuating the mounting stud. For users of the previous generation of post mounting clamps, the same quick-release handle is also sold separately (Item # C15QR).

Insights into HeNe Lasers

Scroll down to read about:

- HeNe Lasers: Handling and Mounting Guidelines

Click here for more insights into lab practices and equipment.

HeNe Lasers: Handling and Mounting Guidelines

Click to Enlarge

Figure 1: The external housing of HeNe lasers is mechanically coupled to the components of the lasing cavity. Stress applied to the external housing can misalign and potentially fracture lasing cavity components, which can negatively impact the quality and power of the output laser beam (red arrow) or lead to laser failure

| 1. | High Reflector Optics | 7. | Anode |

| 2. | Gas Reservoir | 8. | Glass Laser Bore |

| 3. | Outer Housing | 9. | |

| 4. | Glass | 10. | Potting Compound |

| 5. | Glass-Metal Seal | 11. | Cathode |

| 6. | Output Coupling Optics |

HeNe lasers should be handled and mounted with care to protect them from damage.

Never apply a bending force to the laser housing. Stress applied to the laser's external housing can misalign or damage components in the laser cavity. This can:

- Affect the output beam quality.

- Result in reduced output power.

- Affect the beam pointing.

- Cause multimode effects.

Factory packaging protects the HeNe lasers from shocks and vibrations during shipping, but end users directly handle the bare laser housing. Due to this, HeNe lasers are in greater danger of experiencing dangerous stress during handling by the end user.

A result is that the primary cause of damage to HeNe lasers is rough handling after receipt of the laser. In extreme cases, shock and vibrations can shatter or fracture glass components internal to the laser.

To maintain the optimum performance of your HeNe laser, do not drop it, never use force when inserting it into fixture, and use care when installing it into mounts, securing it using cage components or ring accessories that grip the housing, transporting it, and storing it.

HeNe lasers will provide optimum performance over a long lifetime when they are handled gently.

Date of Last Edit: Dec. 4, 2019

| Posted Comments: | |

user

(posted 2020-10-21 14:51:28.85) What is maximum load of C1513/M? llamb

(posted 2020-11-30 08:40:57.0) Thank you for your feedback. We do not currently have a max load spec for the C1513(/M). After discussing with you directly by email, using two C1513/M units to support your ~2 m long, ~6 kg tube would be acceptable. bednaja4

(posted 2016-08-18 09:16:19.26) Hello,

we are looking for laser holder like C1512, but we need to hold diameter of 55mm. Will it work with C1512 or do you have another solution? Thanks, John user

(posted 2014-03-11 18:21:49.387) Please bring back the PM1 and PM2. Thanks. jlow

(posted 2014-03-12 08:39:26.0) Response from Jeremy at Thorlabs: The PM3 and PM4 are designed to provide better clamping force than the PM1 and PM2. Since you did not leave any contact information, can you contact us at techsupport@thorlabs.com to discuss about the reason you need the PM1 and PM2 please? lmorgus

(posted 2011-05-25 13:13:00.0) Response from Laurie at Thorlabs to the anonymous poster: Thank you for noticing an oversight in our recent web update to supercede the PM2 by the PM4. We have updated the overview tab to reflect the current offerings. Thanks again for taking the time to point out the error. user

(posted 2011-05-25 12:52:42.0) Overview references the obsolete PM2, which was replaced by the PM4. |

- ±10° of Coarse Pitch Control

- Accepts Cylindrical Objects Ranging in Diameter from 0.33" to 2.04" (6.5 mm to 51.9 mm)

- Includes Quick-Release Handle for Easy Mounting to Ø1.5" Posts

- One PM4(/M) Clamping Arm Included

The C1512(/M) Post V-Clamp Mount accepts cylindrical objects ranging in diameter from 0.33" to 2.04" (6.5 mm to 51.9 mm), such as HeNe Lasers, High-Magnification Zoom Lenses, and Laser Diode Modules. The angle of the V-clamp may be adjusted within a ±10° range by loosening two 8-32 (M4) cap screws that are located behind the V-clamp's inner edge.

This clamp features a quick-release handle for securing the clamp to a post. The handle contains a 1/4"-20 (M6) threaded stud that engages the part by simply rotating the handle. An internal mechanism allows the handle's rotational position to be adjusted without actuating the mounting stud.

This mount includes one PM4(/M) Clamping Arm, which may be fastened at any of three positions along the outer edge of the V-clamp. Additional PM4(/M) clamping arms are sold below.

- Kinematic Knobs Provide ±2.2° of Pitch and ±2.7° Yaw Control

- Accepts Cylindrical Objects Ranging in Diameter from 0.28" to 2.04" (6.7 mm to 51.9 mm)

- Includes Quick-Release Handle for Easy Mounting to Ø1.5" Posts

- One PM4(/M) Clamping Arm Included

The C1513(/M) Post Kinematic V-Clamp Mount accepts cylindrical objects ranging in diameter from 0.28" to 2.04" (6.7 mm to 51.9 mm), such as HeNe Lasers, High-Magnification Zoom Lenses, and Laser Diode Modules. The two kinematic knobs provide fine control of tip and tilt with ±2.2° of pitch and ±2.7° yaw and an adjustment per revolution of 6 mrad/rev.

This clamp features a quick-release handle for securing the clamp to a post. The 2.03" (51.4 mm) long handle contains a 1/4"-20 (M6) threaded stud that engages the part by simply rotating the handle. An internal ratchet-type mechanism allows for the handle's rotational position to be adjusted without actuating the mounting stud.

This mount includes one PM4(/M) Clamping Arm, which may be fastened at any of three positions along the edge of the clamp. Additional clamping arms are sold below.

The kinematic mechanism consists of a series of hardened chromium steel balls and ball seats that are coupled to heavy-duty springs. This mechanism works with gravity and provides long-term stability.

Click to Enlarge

Clamping Arm Extension Posts with Metric Indicator Groove

Click for Details

Mechanical Drawings

- Provide Clamping Force for Our Platform Mounts

- 6-32 (M4) Threads on Top and Bottom of Post

- PM3(/M): Holds Optics up to 0.97" (24.6 mm) Tall

- PM4(/M): Holds Optics up to 1.61" (40.9 mm) Tall

- Extension Posts Available to Increase Max Optic Height

- PM3SP(/M) with PM3(/M): Hold Optics up to 2.21" (56.1 mm) Tall

- PM4SP(/M) with PM4(/M): Hold Optics up to 3.61" (91.7 mm) Tall

Thorlabs' PM3(/M) and PM4(/M) Clamping Arms use a nylon-tipped setscrew with a 5/64" (2.0 mm) hex to secure optics to our kinematic platform mounts and V-clamps. The PM3(/M) accommodates optics up to 0.97" (24.6 mm) tall and features a 0.69" (17.5 mm) center-to-center distance between the post and the nylon-tipped setscrew. In contrast, the PM4(/M) accommodates optics up to 1.61" (40.9 mm) and features a 1.16" (29.3 mm) center-to-center distance between the post and the nylon-tipped setscrew. The maximum optic height of the PM3(/M) or PM4(/M) Clamping Arms can be extended using our PM3SP(/M) or PM4SP(/M) Extension Posts, respectively. These extension posts are identical to the posts included in each complete clamping arm.

The clamping arm for all items is held to the post using a flexure mechanism that locks with a 5/64" (2.0 mm) balldriver or hex key. The post also offers a through hole for added torque when tightening down the post. Please see the diagram above for additional information.

Click for Details

Left: C15QR Quick-Release Handle Being Attached to the C1511 Post Mounting Clamp

Right: Pull Back to Rotate the Position of the Handle

- Quick-Release Handle for Fast and Repeated Positioning of Post Clamps

- Compatible with Ø1" (Ø25.0 mm) or Ø1.5" Post Clamps that Incorporate a 1/4"-20 (M6) Clamping Screw

- Provides More Control and Feel when Locking and Unlocking a Clamp

- Handle can be Rotated Without Actuating the Locking Screw

- 1/4"-20 (M6) Threads

The C15QR(/M) Quick-Release Handle provides a simple and reliable way of securing a flexure-based Ø1" (Ø25.0 mm) or Ø1.5" post clamp. In many cases a cap screw is used to lock a flexure-based clamp in place on a post, which requires a balldriver for adjustments. Depending on the mounted load, using a balldriver can be difficult, or even unsafe. This quick-release handle mitigates this problem by allowing the clamp to be hand-tightened, ensuring better control over the amount of torque applied to tighten or loosen the clamp. This also decreases the amount of time needed for basic setup and alignment by eliminating the need for additional balldrivers and allowing for a quick way to secure a clamp.

Easily installed by replacing the 1/4"-20 (M6) locking screw in a post clamp, the 2.03" (51.4 mm) long handle contains a 1/4"-20 (M6) threaded stud that engages a part by rotating the handle. Once the handle is tightened to secure a clamp to a post, the internal ratchet-type mechanism allows for the handle's rotational position to be adjusted without actuating the mounting stud. Simply pull the handle outwards to disengage it from the mounting stud, as shown in the image to the right, then rotate it to a more convenient position. This feature ensures that the handle will always be accessible to the user.

Products Home

Products Home

Zoom

Zoom

V-Mounts for Ø1.5" Posts

V-Mounts for Ø1.5" Posts