25 mm Travel Compact Translation Stages, Crossed-Roller Bearings

- 25 mm Travel Provided by Metric Micrometers

- Crossed-Roller Bearings for Superior Angular Deviation and Load Capacity

- Each Stage Ships with Individual Test Data Certificate

- 1-, 2-, or 3-Axis Versions

LX10

Single-Axis Stage

LX20YZ

YZ Stage

LX30

XYZ Stage

LX20

XY Stage

LX20XZ

XZ Stage

LXP1

Grooved Mounting Plate

Please Wait

| Specifications | |||||

|---|---|---|---|---|---|

| Item # | LX10(/M) | LX20(/M) | LX20XZ(/M) | LX20YZ(/M) | LX30(/M) |

| Translation Axes | X | XYa | XZa | YZa | XYZa |

| Travel | 25 mm | ||||

| Angular Deviationb | <125 µrad | ||||

| Vertical Straightnessb,c | <10.0 µm | ||||

| Platform Size | 2.56" x 2.56" (65.0 mm x 65.0 mm) | 2.55" x 2.56" (64.8 mm x 65.0 mm) | |||

| Top Plate Mounting Holes | Seven 1/4"-20 (M6 x 1.0) | ||||

| Bottom Plate Mounting Holes | Four 1/4" (M6) Counterbores Four Ø0.095" (Ø2.4 mm) Alignment Holes |

||||

| Deck Height | 0.98" (25.0 mm) |

1.50" (38.0 mm) |

- | ||

| Horizontal Load Capacity | 41 kg (90 lbs) Max | - | |||

| Vertical Load Capacity | 4 kg (8.8 lbs) Maxd | ||||

| Bearing Type | Crossed-Roller Bearings | ||||

| Micrometer Specifications | |||||

| Micrometer Item # | 150-801ME-H | ||||

| Resolution | 500 µm Translation Per Revolution | ||||

| Travel | 25 mm | ||||

| Micrometer Barrel Size | Ø3/8" (Ø9.5 mm) | ||||

Features

- Self-Contained Stages with Integrated Micrometer Mounts

- Crossed-Roller Bearings for High Load Capacity and Low Angular Deviation

- 1-, 2-, or 3-Axis Versions

- Seven 1/4"-20 (M6 x 1.0) Mounting Holes

- Side-Mounted Metric Micrometer(s) with Ø3/8" (Ø9.5 mm) Barrel

- Each Stage Individually Tested and Shipped with Test Data Certificate

- Mounts to Optical Table Using Four 1/4" (M6) Counterbores

- Grooved Mounting Plate Available for Keyway Accessories

Thorlabs' LX Series Compact Translation Stages provide 25 mm of linear translation with less than 125 µrad of deviation per axis in pitch and yaw over the full range of the stages. Featuring compact footprints, the stages use crossed-roller steel bearings to support precision motion and high load capacities. The monolithic top and bottom plates feature integrated micrometer mounts and are machined from cast tool and jig aluminum for high stability and minimal internal stress.

After each stage is manufactured, the pitch and yaw of the stage are tested. This ensures that each stage meets the stated specifications over the full translation range of the stage. A summary of the test results is provided on an individualized data sheet that ships with each stage. Sample data sheets can be viewed here for the LX10, LX20, and LX30.

The mounting surface includes an array of seven 1/4"-20 (M6) tapped holes with 1/2" (12.5 mm) spacings. Each stage axis is lockable via a side-located 5/64" (2.0 mm) hex screw in a locking bracket to guard against accidental movement. Each stage can be bolted directly to an optical table using four counterbored 1/4" (M6) holes that are revealed by translating the second plate from the bottom, as shown in the image to the left. For XY and XYZ stages, the micrometer attached to this plate blocks one of the mounting holes beneath it; to access this hole, the micrometer must first be removed. The base of each stage also has four Ø2.4 mm alignment holes for use with Ø3/32" dowel pins.

Click to Enlarge

These stages can be secured to a breadboard using counterbored holes in the bottom plate. The holes can be accessed by translating the platform, as shown with the LX10 stage above.

These stages come equipped with a metric micrometer head with 500 µm of travel per revolution for each axis. The micrometer can be translated using the knurled knob or, for finer control, a 5/64" (2.0 mm) hex key. The micrometer can be removed and replaced by loosening the side-located flexure clamp with a 5/64" (2.0 mm) hex key. This flexure clamp can hold any micrometer that has a Ø3/8" (Ø9.5 mm) mounting barrel.

Each stage is designed as a standalone stage with a specific number of axes; as such, single-axis stages cannot be combined into multi-axis stages and multi-axis stages cannot be disassembled into single-axis stages. For modular multi-axis stages, please see our quick-connect 25 mm travel stages and compact, quick-connect 25 mm travel stages.

We also offer the LXP1(/M) Mounting Plate with a 3 mm 'crossed groove' design that is ideal for use with our keyway accessories, which can be secured with AMA010(/M) cleats in 6-32 (M3) taps. The 6-32 (M4) taps are suited for use with our Adjustable Clamping Arms.

Note: If removing the micrometer, ensure either that the locking bracket is fully tightened or that the spindle is fully retracted and no longer engaged with the moving body of the stage. Failure to do so could result in damage to the stage or require it to be recalibrated to meet its specified performance.

Insights into Best Lab Practices

Scroll down to read about a practice we follow when setting up lab equipment.

- Bases: For Stability Orient the Side with the Undercut Down

Click here for more insights into lab practices and equipment.

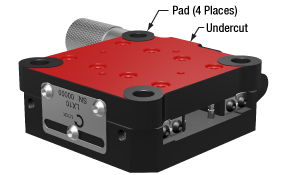

Bases: For Stability Orient the Side with the Undercut Down

An undercut is machined into the bottom surface of bases like the BA2 (Figures 1 and 2). The undercut creates feet, which are called pads. For maximum stability, the base should be oriented with its pads in contact with the table or breadboard.

The top surface of the base does not have an undercut and is the intended mounting surface for components.

Mounting the base upside down could result in the base rocking on the table or breadboard, or the base may exhibit other mechanical instability.

The Pads are Flatter than the Top Surface

The undercut is key to the flatness of the pads. The pads are machined flat after the undercut is made.

Friction heats the pads during the processing step that provides them with a maximally flat profile. By reducing the surface area of the pads, the undercut reduces the amount of heat generated during this step.

It is beneficial to minimize the heat generated during machining. Metal expands when heated, and the uneven heating that occurs during machining can distort the dimensions of the part. If the dimensions of the part are distorted during machining, the part can be left with high spots and other undesirable features after it cools. This can cause instability and misalignment when using the part.

Precision Instruments and Devices have Pads

Another example of a component with pads is the LX10 linear stage shown in Figure 3.

Click to Enlarge

Figure 3: Pads machined into Thorlabs' devices improve their stability when bolted in place. The pads are highly flat and project above the undercut region, which is highlighted red. The undercut limits the contact area with the table or breadboard.

Click to Enlarge

Figure 2: This view of the bottom shows the undercut highlighted in red. By removing this material, the pads can be made maximally flat.

Click to Enlarge

Figure 1: For optimal stability, the base should be mounted with the undercut facing the optical table or breadboard.

Date of Last Edit: Dec. 9, 2019

| Posted Comments: | |

Friederike Ewald

(posted 2023-11-14 16:43:29.18) Hi,

being interested in buying some stages of this LX10/M or LX20/M series, I was wondering if they were compatible with the stepper actuator model ZST225B, as this is not expressly mentioned.

Thank you in advance for your advice.

Best regards,

Friederike Ewald jdelia

(posted 2023-11-14 02:16:07.0) Thank you for contacting Thorlabs. Yes, the ZST225B is compatible with both the LX10/M and LX20/M after removing the micrometer. Please note: If removing the micrometer, ensure either that the locking bracket is fully tightened or that the spindle is fully retracted and no longer engaged with the moving body of the stage. Failure to do so could result in damage to the stage or require it to be recalibrated to meet its specified performance. John Good

(posted 2023-09-05 12:12:30.183) What is the spring return force on the LX10/M? jdelia

(posted 2023-09-12 10:29:09.0) Thank you for contacting Thorlabs. The two component springs within the LX10/M have a free length of 1" and a spring rate of 1.4 lbs/in. I have also reached out to you directly to further discuss your application and the specifications of these springs. Craig Brideau

(posted 2019-10-03 16:19:18.107) Would an XZ or YZ configuration be possible? YLohia

(posted 2019-10-04 12:10:57.0) Hello, thank you for contacting Thorlabs. I have posted your request on our internal product engineering forum for further consideration. user

(posted 2019-07-04 03:02:10.527) i can t dowload your product mmcclure

(posted 2019-07-05 04:25:10.0) Hello, thank you for contacting us. We have corrected an issue with the STEP file, which can now be downloaded properly. I have reached out to you directly to discuss if the issue you mention is resolved. mojtaba.zamani.a

(posted 2017-06-01 16:34:01.73) can these stages work used at xyz configuration? tfrisch

(posted 2017-06-22 09:40:00.0) Hello, thank you for contacting Thorlabs. XY and XYZ versions are in development. I will reach out to you directly. I can assist with XYZ solutions until these monolithic stages are released. |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

- 25 mm Single-Axis Translation

- 0.98" (25 mm) Deck Height

- 500 µm Translation per Micrometer Revolution

The LX10(/M) stage allows for 25 mm of travel along the X axis. The stage comes with a 150-801ME-H micrometer. Please note that this stage is shorter than the multi-axis LX20(/M) stage by 0.52" (13 mm). Directly replacing one with the other might require realignment of other fixtures.

For more detailed information, please refer to the Specifications table above.

Click to Enlarge

The upper micrometer must be removed to access one of the mounting holes in the base.

- 25 mm Translation in X and Y Axes

- 1.50" (38.0 mm) Deck Height

- 500 µm Translation per Micrometer Revolution

- Compact Monolithic Construction for Superior Performance

The LX20(/M) stage allows for 25 mm of travel along the X and Y axes. The stage comes with two 150-801ME-H micrometers. Please note that this stage is taller than the single-axis LX10(/M) stage by 0.52" (13 mm). Directly replacing one with the other might require realignment of other fixtures.

This stage can be bolted directly to the optical table using four counterbored 1/4" (M6) holes that are revealed by translating the middle plate. The micrometer attached to this plate blocks one of the mounting holes beneath it; to access this hole, the micrometer must first be removed, as illustrated in the photo to the right. The base of the stage also has four Ø2.4 mm alignment holes for use with Ø3/32" dowel pins.

Note: If removing the micrometer, ensure either that the locking bracket is fully tightened or that the spindle is fully retracted and no longer engaged with the moving body of the stage. Failure to do so could result in damage to the stage or require it to be recalibrated to meet its specified performance.

For more detailed information, please see the Specifications table above.

- 25 mm Translation in X and Z Axes

- 500 µm Translation per Micrometer Revolution

- Compact Monolithic Construction for Superior Performance

The LX20XZ(/M) stage allows for 25 mm of travel along the X and Z axes, where X-axis translation is parallel to the face of the Z-axis stage. The stage comes with two 150-801ME-H micrometers. Please note that this stage is shorter than the three-axis LX30(/M) stage by 0.51" (12.9 mm). Directly replacing one with the other might require realignment of other fixtures.

This stage can be bolted directly to the optical table using four counterbored 1/4" (M6) holes that are revealed by translating the middle plate. The base of the stage also has four Ø2.4 mm alignment holes for use with Ø3/32" dowel pins.

Note: If removing the micrometer, ensure either that the locking bracket is fully tightened or that the spindle is fully retracted and no longer engaged with the moving body of the stage. Failure to do so could result in damage to the stage or require it to be recalibrated to meet its specified performance.

For more detailed information, please see the Specifications table above.

- 25 mm Translation in Y and Z Axes

- 500 µm Translation per Micrometer Revolution

- Compact Monolithic Construction for Superior Performance

The LX20YZ(/M) stage allows for 25 mm of travel along the Y and Z axes, where Y-axis translation is perpendicular to the face of the Z-axis stage. The stage comes with two 150-801ME-H micrometers. Please note that this stage is shorter than the three-axis LX30(/M) stage by 0.51" (12.9 mm). Directly replacing one with the other might require realignment of other fixtures.

This stage can be bolted directly to the optical table using four counterbored 1/4" (M6) holes that are revealed by translating the middle plate. The base of the stage also has four Ø2.4 mm alignment holes for use with Ø3/32" dowel pins.

Note: If removing the micrometer, ensure either that the locking bracket is fully tightened or that the spindle is fully retracted and no longer engaged with the moving body of the stage. Failure to do so could result in damage to the stage or require it to be recalibrated to meet its specified performance.

For more detailed information, please see the Specifications table above.

Click to Enlarge

The middle micrometer must be removed to access one of the mounting holes in the base.

- 25 mm Translation in X, Y, and Z Axes

- 500 µm Translation per Micrometer Revolution

- Compact Monolithic Construction for Superior Performance

The LX30(/M) stage allows for 25 mm of travel along the X, Y, and Z axes. The stage comes with three 150-801ME-H micrometers. Please note that this stage is taller than the two-axis LX20YZ(/M) stage by 0.51" (12.9 mm). Directly replacing one with the other might require realignment of other fixtures.

This stage can be bolted directly to the optical table using four counterbored 1/4" (M6) holes that are revealed by translating the lower plate of the stage. The micrometer attached to this plate blocks one of the mounting holes beneath it; to access this hole, the micrometer must first be removed, as illustrated in the photo to the right. The base of the stage also has four Ø2.4 mm alignment holes for use with Ø3/32" dowel pins.

Note: If removing the micrometer, ensure either that the locking bracket is fully tightened or that the spindle is fully retracted and no longer engaged with the moving body of the stage. Failure to do so could result in damage to the stage or require it to be recalibrated to meet its specified performance.

For more detailed information, please see the Specifications table above.

Click to Enlarge

Hole Pattern of the LXP1/M

Click to Enlarge

Hole Pattern of the LXP1

- Two Perpendicular 3 mm Grooves Designed for Many Keyway Accessories

- Array of Tapped Holes for Additional Mounting Options

- Two Counterbores for 1/4"-20 (M6 x 1.0) Screws

- Imperial Plate:

- Twenty-Four 6-32 Tapped Holes

- Eleven 8-32 Tapped Holes

- Metric Plate:

- Twenty M3 Tapped Holes

- Fifteen M4 Tapped Holes

Click to Enlarge

HCS013 Mount Attached to an LX10 Stage via the LXP1 Mounting Plate.

The LXP1(/M) Grooved Mounting Plate provides additional mounting options for the LX series of 25 mm Translation Stages. The 3 mm grooved design is necessary for many keyway accessories (e.g., HCS013 RMS-Threaded Flexure Stage Mount shown to the right).

In addition to the 3 mm grooves, the plates have an array of 6-32 and 8-32 (M3 and M4) tapped holes for a variety of different mounting applications. The 6-32 (M4) taps can be used for mounting our clamping arms, as shown in the images to the lower right. The remaining 6-32 (M3) taps are compatible with the AMA010(/M) mounting cleats, which are ideal for securing the keyway accessories. To attach the mounting plate to the LX stages, four 1/4"-20 (M6) are included.

Products Home

Products Home

Zoom

Zoom

Compact Crossed Roller Bearing

Compact Crossed Roller Bearing