Fluoride Glass Optical Fiber

- Single Mode and Multimode Fluoride Fiber Manufactured In-House

- Transmissive from the UV to 5.5 µm

- Stable in Typical Lab Environments and Easy to Handle

- Core Refractive Index Similar to Silica Glass

Multimode Fluoride Bare Fiber

Fluoride Fiber Cross Section

(Not to Scale)

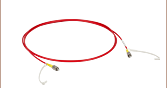

Custom Ruggedized Fluoride Patch Cable

Please Wait

Applications

- Spectroscopy

- Fiber Lasers

- Supercontinuum Light Sources

- Environmental Monitoring

- Surgical Lasers

- Chemical Sensing

- IR Imaging

Click to Enlarge

Click for Raw Data

Compared to standard silica glass fibers, Thorlabs' single mode

fluoride fibers are transmissive at much longer wavelengths.

Features

- Fluoride Glass Fibers Manufactured at Thorlabs' Fiber

Draw Facility- Fluorozirconate (ZBLAN)† for 285 nm - 4.5 µm

- Fluoroindate (InF3) for 310 nm - 5.5 µm

- World-Class Attenuation, Mechanical Strength, and

Geometry Control - Bare Fibers, Patch Cables, Fiber Bundles, and Reflection/Backscatter Probes Available

- Flexible Manufacturing Processes for Catalog and

Custom Products (See Manufacturing Tab for Details)

Thorlabs manufactures an extensive family of mid-IR fluoride fiber using proprietary techniques that provide world-class purity, precision, and strength. These techniques give us excellent control over the fibers' optical and mechanical properties, allowing a wide range of configurations to be drawn. For details, please see the Manufacturing tab.

Based upon ZBLAN† (fluorozirconate) or InF3 (fluoroindate) glasses, our fluoride fibers feature high transmission over the 285 nm - 4.5 µm or 310 nm - 5.5 µm spectral range, respectively. Fluoride fibers offer low attenuation in the mid-IR wavelength range (see the Graphs tab), aided by an extremely low hydroxyl ion (OH) content. The refractive index of fluoride glass is near that of silica; therefore, optical fibers manufactured using fluoride glass exhibit lower return losses and Fresnel reflections than chalcogenide glass fibers.

Products available from stock with same-day shipping include single mode and multimode patch cables, as well as bifurcated fiber bundles for transmission applications and reflection/backscatter probes designed for spectroscopy. Bare single mode fluoride fiber is available from stock and will typically ship within two days. Bare multimode fluoride fiber is available upon request by contacting Tech Sales.

Since fluoride glass is softer than standard silica glass, extra care should be taken while cleaning and handling. See the Handling tab for suggested procedures.

† ZBLAN and ZrF4 are used interchangeably to refer to fluorozirconate glass.

Custom Fluoride Fiber and Patch Cables

If our standard offerings do not meet your needs, please contact us to discuss customization and potential fiber draws. Some of the many customization options we provide for fluoride fibers and patch cables include:

- Hand-Selected Extra-Low-Loss Fluoride Fibers to Meet Strict Attenuation Requirements

- Custom Core and Cladding Geometries

- Dual-Polymer Claddings Available

- Increased Power Handling Capabilities

- Custom Options: Fiber Type, Length, Termination, and Tubing

- OEM Patch Cables: Designed for Application Requirements

- AR-Coated Patch Cables

- Ruggedized Cabling for Harsh Environments

Fluoride Fibers and Components |

|||

|

|

|

|

|

|

|

|

View our recorded webinar, in which we highlight our manufacturing techniques, the history of fluoride fiber R&D, and the state of fluoride fiber technology today and in the future.

Thorlabs manufactures ZBLAN zirconium fluoride (ZrF4) and indium fluoride (InF3) fibers at our vertically integrated fiber draw facility. The facility handles raw materials, glass preforms, fiber draw, and patch cable production, all in the same location. By controlling the process from start to finish, Thorlabs can ensure fibers consistently meet world-class specifications, including low attenuation, high mechanical strength, and precise geometry control.

The facility, located in Newton, NJ, USA, is well-equipped for high-volume manufacturing and is capable of producing many kilometers of fiber with consistent performance. In addition, because the fiber stays within Thorlabs' facilities from start to finish, the manufacturing process can be adjusted to accommodate unique custom orders or R&D needs.

Fluoride Characteristics

Fluoride fibers are ideal for transmission in the mid-IR wavelength range, and Thorlabs' fibers feature low attenuation over this range as a result of stringent manufacturing processes yielding an extremely low hydroxyl ion (OH) content. Fluoride fibers also have lower refractive indices and lower chromatic dispersion when compared to other fibers that offer transmission in the mid-IR range, such as chalcogenide glass fibers. Thorlabs' tightly controlled processes mitigate scattering and point defects in the fiber, as well as eliminate micro-crystallization in the glass matrix.

Fluoride Fiber Characterization and Testing

In addition to manufacturing fiber, Thorlabs offers testing and characterization services for our fiber products. We precisely measure the properties of each drawn fiber to ensure that it meets our high standards of quality. Extensive testing also provides feedback for our fiber draw team, enabling tight control of each step in the manufacturing process. Customers can request custom testing of any Thorlabs-manufactured fiber, which is then provided with the shipped fiber. Testing of third-party fiber samples provided by customers is also available upon request.

Available tests and services include:

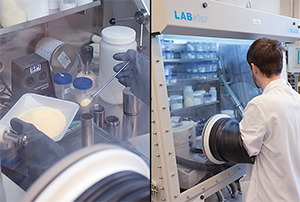

Click to Enlarge

A Thorlabs engineer mixes raw materials in our fluoride glass fabrication facility.

Click to Enlarge

A Glass Drop During the Fiber Draw Process

- Spectral Attenuation Measurement

- UV / Visible / NIR / MIR Wavelength Range

- SM or MM Fiber and Bulk Glass

- SM Fiber Cutoff Wavelength Measurement

- Fiber NA Measurement

- Fiber Glass / Coating Geometry Measurement

with Sub-µm Accuracy - MIR High-Power Screening for MM Fibers

- Fiber Tensile Strength Testing

- Defect / Break Analysis

- Degree of Cure Testing for Fiber Coatings

Request testing for Thorlabs or third-party fibers by

contacting Tech Sales.

Click to Enlarge

These graphs show Thorlabs' steady improvement in the average attenuation of all fiber draws during the given year.

Technical Team

Thorlabs' team of MIR fiber researchers and engineers has many years of experience in fluoride glass research and development, production, and fiber draw. Their knowledge and expertise have resulted in consistent improvement in the quality of our fluoride fiber. See the graphs to the left for the progression of our fluoride fiber performance.

Custom Fluoride Fiber and Patch Cables

If our standard offerings do not meet your needs, please contact Tech Support to discuss customization and potential fiber draws. Some of the many customization options we provide for fluoride fibers and patch cables include:

Bare Fiber

|

Patch Cables

|

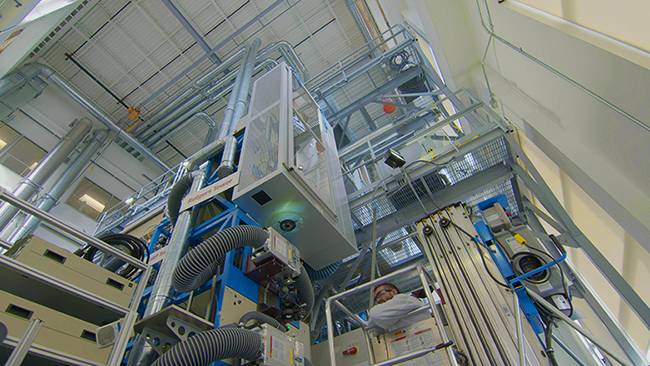

Click to Enlarge

Thorlabs' Fiber Draw Tower

| Fluoride Glass Properties Graphs (Click to Enlarge) | |||

|---|---|---|---|

| Material | Transmission through Bulk Glass Sample |

Index of Refraction | Numerical Aperture (NA) |

| ZBLAN Raw Data for All ZBLAN Graphs |

|

|

|

| InF3 Raw Data for All InF3 Graphs |

|

|

|

| Fluoride Fiber Performance Graphs (Click to Enlarge) | |||

|---|---|---|---|

| Material | Typical Attenuation, Single Mode | Typical Attenuation, Multimode | Attenuation Repeatability, Multimode |

| ZBLAN Raw Data for All ZBLAN Graphs |

|

|

|

| InF3 Raw Data for All InF3 Graphs |

|

|

|

Fibers and Components

Thorlabs' selection of fluoride fiber products includes bare fiber, patch cables, and fiber bundles. The table below contains a summary of our available products containing each type of fiber.

| Fiber Type | Single Mode | Multimode | Dual-Clad Multimode | ||

|---|---|---|---|---|---|

| ZBLANa | InF3 | ZBLANa | InF3 | InF3 | |

| Key Attributes | 2.3 µm - 4.1 µm SM Operation | 3.2 µm - 5.5 µm SM Operation | 285 nm - 4.5 µm Transmission Range |

310 nm - 5.5 µm Transmission Range |

310 nm - 5.5 µm Transmission Range |

| 285 nm - 4.1 µm Transmission Range |

310 nm - 5.5 µm Transmission Range |

Polymer Second Cladding for High-Power Applications (See Dual-Clad Fiber Tab for Details) |

|||

| Bare Fiber | 10.5 µm Mode Field Diameter | 11.0 µm Mode Field Diameter | Core Size: ∅50 µm - ∅600 µm | Core Size: ∅100 µm or ∅200 µm | Core Size: ∅100 µm or ∅200 µm |

| Patch Cables | FC/PC-Compatible, FC/APC-Compatible, or Hybrid | FC/PC-Compatible, FC/APC-Compatible, or Hybrid | FC/PC-Compatible or SMA905 | FC/PC-Compatible or SMA905 AR-Coated Patch Cable Vacuum-Compatible Patch Cable |

- |

| Fiber Bundles | - | - | Bifurcated Fiber Bundle Reflection/Backscatter Probes |

- | - |

| Vacuum Flanges | - | - | - | KF40 Flange Fiber Feedthrough | - |

Other Products Incorporating Our Fluoride Fibers

Our fluoride fiber capabilities have been used in the development of our other products, with custom versions of our fibers being used in some of our active fiber devices. Three examples are shown below.

Click to Enlarge

Our SC4500 Supercontinuum Laser Source uses a custom single mode InF3 fiber to achieve Mid-IR supercontinuum operation in the compact, stable format provided by a

fiber device.

Click to Enlarge

Our PDFA100 Series O-Band Fiber Amplifiers use a praseodymium-doped single mode ZBLAN fiber. Unlike silica glass, ZBLAN is able to support the key excited state of praseodymium, which allows for the construction of a fiber amplifier operating in the O-band.

Click to Enlarge

Our LFL2700 Series Mid-IR Fiber Laser Sources incorporate an erbium-doped single mode ZBLAN fiber to provide high beam quality near 2.7 µm.

Click to Enlarge

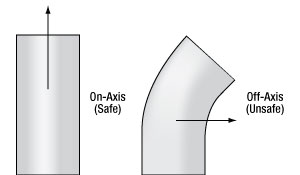

This diagram compares on-axis tension, which can be safely applied, to off-axis tension, which can induce unsafe curvature and damage the fiber.

Click to Enlarge

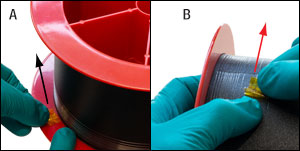

The recommended procedure for removing tape from the bare fiber spools is shown in this image. The tape should be pulled parallel to the fiber when removing, while the other hand applies gentle force to stabilize the fiber.

Click to Enlarge

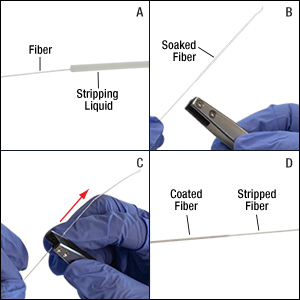

These images depict the recommended stripping procedure. A: Immerse the target fiber secion in stripping liquid.

B-C: Gently pinch the base of the soaked section with FSGT tweezers and pull toward the end of the fiber.

D: The coating should slide off, leaving a stripped section.

The material properties of fluoride glass differ from those of silica glass. This tab details recommended handling procedures for our fluoride fibers and patch cables.

Safety and Disposal

ZBLAN and InF3 glasses may present health risks. Information about the composition of our fluoride fibers is available from Tech Support upon request. When handling bare, stripped fluoride fiber, chemically resistant gloves such as our nitrile gloves should always be worn. Fiber shards generated from cleaving should be disposed of in a sharps container such as our FTDU fiber optic disposal unit.

Thorlabs will accept and dispose of any fluoride fiber or filled disposal units that you wish to discard. Please contact Tech Support before returning fiber or filled disposal units. If you wish to dispose of fiber locally, please follow all applicable local laws and regulations.

Storage

Because fluoride glass is softer than silica glass, exposed end faces are easily scratched during storage, and care should be taken to ensure that they are not exposed to mechanical abrasion. Storage under normal lab temperatures and humidities will not affect the integrity of the fiber. Prolonged, direct contact with liquid water or water vapor should be avoided.

Bending and Tension

Fluoride fiber is strong in tension, but can break easily if forces are applied off-axis or if it is bent to a small radius. These fibers should never be bent to smaller than their short-term bend radii. Moderate on-axis forces can be safely applied to the fiber, such as tension applied during spooling. The diagram to the right demonstrates safe on-axis tension and unsafe off-asix tension.

Our bare fluoride fibers ship on a spool, with their ends taped to the spool body. When removing the fiber, the tape should be pulled parallel to the fiber, as shown in the image to the top right.

For protection, our fluoride patch cables are jacketed with PVDF furcation tubing or stainless steel tubing that is stiffer than the jackets used in typical patch cables. As long as the jacket is not forced to bend below its specified minimum radius, the fiber will remain intact. For out patch cables with PVDF jackets, the tubing will become discolored if the bending limit is exceeded. Our patch cables with stainless steel tubing are designed so that the tubing mechanically limits the fiber to be unable to bend below its minimum radius.

Stripping

Fluoride fibers are susceptible to damage when conventional mechanical stripping techniques are used, owing to the softness of the glass. Our FSGT Coating Stripping Tweezers can be used along with a chemical stripping agent to effectively strip these fibers without scratching or nicking the cladding.

To strip a fiber, the coating should first be exposed to a stripping liquid such as a paint stripper for three to five minutes. Placing the stripping liquid in a long vessel such as a syringe with a long tip is recommended to increase ease of application. If using a gel-type stripper, it can be applied manually to the exterior of the fiber. Note that the required soaking time will depend on the particuar stripping agent being used as well as the chemical composition of the coating. For example, if a dicholomethane (DCM) based stripping liquid is used, the required time may be shorter.

The coating on the section of the fiber soaked in stripping liquid will visibly swell, as seen in section B of the image to the right. A pair of FSGT tweezers can then be used to gently pinch the fiber in the soaked section, and pull toward the end of the fiber. Care should be taken to ensure that only moderate pressure is applied, or else the fiber may break. The soaked coating should slide off the end of the fiber, leaving the cladding exposed. If residue remains on the stripped section, it can be cleaned as detailed below.

Refer to any safety documentation for the chemical stripping agent before use.

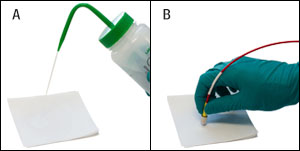

Click to Enlarge

These images depict the recommended procedure for cleaning end faces with a solvent.

A: Wet a stack of five or more TCW604 wipes with an appropriate solvent (see the text for examples).

B: Gently pass the fiber end face across the wet wipe.

Cleaning

Because fluoride glass is soft, end faces and stripped sections of our fluoride fibers and patch cables can be easily scratched during cleaning. If particulates are present on the glass surface, first try to remove them using compressed air. If compressed air is insufficient, then an appropriate solvent can be used with our TCW604 TechniCloth®† Lint-Free Wipes to clean the tip, as shown in the image to the left. Methanol and isopropanol are examples of appropriate solvents, while acetone is unsuitable. Wiping with a dry cloth is not recommended as it may scratch the surface.

Please note that Kimwipes®†† are extremely likely to scratch the fiber tip and should not be used.

Cleaving

Our fluoride fibers can be cleaved using a tension-and-scribe cleaver such as our Vytran® LDC401 large-diameter fiber cleaver. Note that cleaving these fibers may generate shards. Safety glasses and chemically resistant gloves should always be worn when cleaving.

†TechniCloth® is a registered trademark of the Illinois Tool Works, Inc. Corporation.

††Kimwipes® is a registered trademark of the Kimberly-Clark Corporation.

Click to Enlarge

Microbend Loss in Dual-Clad Fiber: Light that leaks out of the core propagates within the first cladding. The light exits the fiber over a greater area with lower intensity, avoiding damage to the fiber.

Click to Enlarge

Microbend Loss in Standard Fiber: Light that leaks out at a single spot has high intensity and can damage the fiber.

Multimode Dual-Clad Fiber for High Power

- Second Cladding Creates Additional Waveguide Layer

- Reduces Risk of Damage Due to Light Leakage

- Ideal for High Power

- Contact Tech Sales to Order

Our unique dual-clad fiber is designed for delivery of high power beams. Light propagates in the core of the fiber due to total internal reflection upon hitting the interface with the cladding. In a perfect fiber, the light is reflected completely at each point and propagates through the fiber core. However, certain imperfections can cause light to exit the core and leak into the cladding; such imperfections include bends in the fiber cable, microbends in the layers of the fiber, and defects.

In a single-clad fiber, the light may leak out of the fiber at a single spot. This high-intensity spot can easily burn or otherwise damage the fiber. In contrast, double-clad fiber uses a second cladding as a light guide to distribute some of the light leakage along a length of the fiber. This significantly reduces the risk of damage, as the intensity of the leakage is greatly reduced. The images above illustrate the effect of the second cladding in preventing damage.

See the Specs tab for specifications for our dual-clad fiber, or contact Tech Support to discuss custom dual-clad fiber options.

| Posted Comments: | |

Daniel Humberto Martínez

(posted 2021-11-16 02:14:55.273) Hi,

My research group bought a ZBLAN Zirconium Fluoride (ZrF4) fiber (P3-23Z-FC-5), which we use for Supercontinuum Generation. In order to carry out simulations, could you provide us with the non-linear coefficients of the fiber or give us some information or reference in this regard?.

I am awaiting your response

Thank you YLohia

(posted 2021-11-23 02:04:54.0) Hello, thank you for contacting Thorlabs. We don’t spec the non-linear coefficient but the value found in the literature for n2 is 2.1 x 10^-20 m^2/W. Please note that Thorlabs doesn't guarantee this value as we have not tested this parameter. Ye Yujie

(posted 2021-05-20 13:38:38.163) 中红外光纤的纤芯、包层折射率和直径 YLohia

(posted 2021-05-20 10:22:37.0) Hello, an applications engineer from our team in China (techsupport-cn@thorlabs.com) will discuss this directly with you. YLohia

(posted 2021-05-20 10:22:37.0) Hello, an applications engineer from our team in China (techsupport-cn@thorlabs.com) will discuss this directly with you. Jun Zhao

(posted 2020-07-28 17:15:42.74) Could you suggest and quote for InF3 fiber with core size of 10um? nbayconich

(posted 2020-07-28 11:15:23.0) Thank you for contacting Thorlabs, I will reach out to you directly to discuss our custom capabilities. Ian McLaughlin

(posted 2019-08-28 14:40:21.59) Please provide a quote for the Mid-Infrared Optical Fiber nbayconich

(posted 2019-08-28 04:18:38.0) Thank you for contacting Thorlabs. I will reach out to you directly to discuss our custom capabilities and quote you a custom patch cable.

For future custom requests please contact techsupport@thorlabs.com directly or you can request a quote from the "Request Quote" link above the feedback section. todd

(posted 2017-03-03 11:36:46.65) What is the fluoride fiber buffer material? Is the buffer strippable? Once I know this I will figure out how much fiber I will need a quote for. tfrisch

(posted 2017-03-13 02:41:45.0) Hello, thank you for contacting Thorlabs. The buffer is acrylate, and I will contact you directly on how the recommended handling differs from silica fibers. ilindsay

(posted 2015-08-27 15:41:39.307) Hi.

Can you comment on the end preparation of your mid-IR (fluoride) fibers, e.g. differences from SiO2 fibers in terms of cleaving and polishing techniques in the case of applications where connectors are not appropriate? besembeson

(posted 2015-09-29 08:59:55.0) Response from Bweh at Thorlabs USA: We recommend Thorlabs Vytran products, such as the LDC-400 (http://vytran.com/product/ldc-400) for cleaving bare fiber. Polishing is only relevant when terminating fiber with a connector and it is different with these mid-IR fibers. I will follow-up with you for further guidance with these if needed. |

Products Home

Products Home

Fluoride Fiber Overview

Fluoride Fiber Overview