Optical Breadboards, Intrinsically Damped, 58 mm Thick

- Plated Steel Honeycomb Core Construction

- Stainless Steel Top and Bottom Skins

- Lightweight Design

- 58 mm Thick

B1218FX

12" x 18"

Please Wait

| Specificationsa | ||

|---|---|---|

| Construction | ||

| Breadboard Thickness | 58 mm (2.28") | |

| Top Skin Flatness | ±0.15 mm (±0.006") Over Any 600 mm2 | |

| Working Surface | 430 Grade Stainless Steel Top Plate | |

| Core Construction | High-Density Plated Steel Honeycomb 0.26 mm Thick |

|

| Dampingb | Intrinsic | |

| Compatible Mounting Options | Breadboard Frames and Feet ScienceDesk Frames |

|

| Mounting Holes | Imperial | Metric |

| Threads and Spacing | 1/4"-20 Tapped Holes on 1" Centers | M6 Tapped Holes on 25 mm Centers |

| Distance from Edge to First Holes | 0.5" from Table Edge on all Sides | 12.5 mm from Table Edge on all Sides |

| Maximum Screw Depth | 54 mm [16.0 mm for Outer Border Holes] | |

Features

- Thickness: 58 mm

- Sizes from 300 mm x 450 mm (12" x 18") to 900 mm x 1800 mm

(36" x 72") are Available - Top Skin: ±0.15 mm (±0.006") Surface Flatness over any 600 mm x 600 mm Area

- Stainless Steel Top and Bottom Skins with uPVC Side Panels

- Approximately 25% Lighter than our Honeycomb Core Nexus® Breadboards

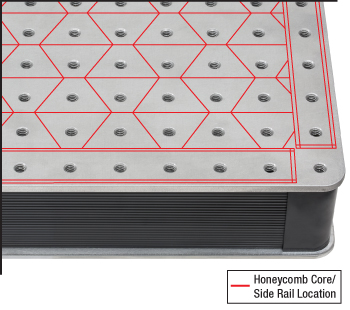

Thorlabs' 58 mm thick optical breadboards are offered in a variety of lengths and widths from 300 mm x 450 mm (12" x 18") to 900 mm x 1800 mm (36" x 72"). The stainless steel top and bottom skins are 5 mm and 3 mm thick, respectively, and have a matte finish. The top skin is precision-machined with a surface flatness of ±0.15 mm (±0.006") over any 600 mm x 600 mm area. Metric breadboards have M6 mounting holes on 25 mm centers with a 12.5 mm border at the edges, while imperial breadboards have 1/4"-20 mounting holes on 1" centers with a 0.5" border at the edges. The maximum screw depth of these mounting holes is 54 mm, except for the outer border holes which have a maximum screw depth of 16.0 mm. The screw depth is unimpeded by the honeycomb structure, as shown in Figure 1.1.

These breadboards are intrinsically damped and are an ideal solution for applications requiring minimal vibration damping. The 0.26 mm thick precision-formed honeycomb core extends from the top to bottom skin without intermediate layers, leading to a stiff and stable board as large as 900 x 1800 x 58 mm (36" x 72" x 2.28"). When paired with the 5 mm thick top skin these breadboards offer good rigidity and damping performace.

Click to Enlarge

Figure 1.1 Outline of the honeycomb core location on an optical breadboard. The core does not intersect with any screw holes.

As the size of any breadboard is increased the chance for static deflection will rise, especially when high loads are being used. To increase the rigidity of the system and minimize static deflection, we recommend using a thicker breadboard, such as our 110 mm thick Nexus Breadboard. Static deflection is a factor when slight variations of the optical axis height are detrimental. A thicker breadboard will help maintain the optical axis height throughout the system and simplify long-distance alignments. For more information regarding breadboard design and vibration damping please see our Vibration Isolation Tutorial.

For a comparison of our breadboard options please see our BB Selection Guide tab. Custom sizes and options are also available, contact Tech Support for more information.

Support Options

Isolation Feet

We offer passive and active self-leveling isolator feet for mounting a breadboard on top of a table. They can support a variety of breadboard sizes and loads and can be easily attached to any breadboad.

ScienceDesks™

Our ScienceDesk line of breadboard frames are high-quality ergonomic supports optimized for applications where the user will be seated. They are available with rigid, passive, or active vibration isolators, and feature a modular system of accessories. ScienceDesk frames are available to fit many of our breadboards sized from 600 mm x 900 mm (24" x 36") to 900 mm x 1200 mm (36" x 48").

Breadboard Frames

We also offer Breadboard Frames available with rigid supports, or with passive or self-leveling active vibration isolation.

Click to Enlarge

Figure 2.1 Comparison of the compliance curves for both the B6090A Nexus and B6090AX Optical Breadboards. Our intrinsically damped breadboards are ideal for applications requiring minimal damping, while our line of Nexus Breadboards is highly recommended when high-vibration damping and minimal deflection are necessary. See the Vibration Isolation Tutorial for more information on compliance.

| Specifications | ||

|---|---|---|

| Construction | ||

| Breadboard Thickness | 58 mm (2.28") | |

| Top Skin Flatness | ±0.15 mm (±0.006") Over Any 600 mm x 600 mm Area |

|

| Top Plate | 5 mm (0.20") Thick Stainless Steel 4003 Grade Working Surface |

|

| Bottom Plate | 3 mm (0.12") Thick Stainless Steel 4003 Grade |

|

| Core Construction | High-Density Plated Steel Honeycomb 0.26 mm Thick |

|

| Dampinga | Intrinsic | |

| Side Panels | Unplasticized Polyvinyl Chloride (uPVC) | |

| Top Surface Finish | Machined Matte Finish | |

| Compatible Mounting Options | Breadboard Frames and Isolators ScienceDesk Frames |

|

| Mounting Holes | Imperial | Metric |

| Threads and Spacing | 1/4"-20 Tapped Holes on 1" Centers | M6 Tapped Holes on 25 mm Centers |

| Distance from Edge to First Holes | 0.5" from Table Edge on all Sides | 12.5 mm from Table Edge on all Sides |

| Maximum Screw Depth | 54 mm [16.0 mm for Outer Border Holes] | |

| Sealed Holes | No | |

Imperial Breadboard Dimensions & Weight

| Item # | Dimensions (W x L x H) |

# of Tapped Holes |

Unpacked Weight |

Packaged Shipping Weight |

Packaged Dimensions |

|---|---|---|---|---|---|

| B1218FX | 12" x 18" x 2.28" | 160 | 22.71 lbs | 31.97 lbs | 14.6" x 20.5" x 5.1" |

| B1224FX | 12" x 24" x 2.28" | 220 | 30.20 lbs | 46.30 lbs | 15.0" x 26.8" x 5.5" |

| B1824FX | 18" x 24" x 2.28" | 352 | 45.19 lbs | 66.14 lbs | 20.5" x 26.4" x 5.5" |

| B2424FX | 24" x 24" x 2.28" | 484 | 60.19 lbs | 97.00 lbs | 26.4" x 26.4" x 5.5" |

| B2436FX | 24" x 36" x 2.28" | 748 | 90.17 lbs | 136.69 lbs | 26.4" x 38.6" x 9.1" |

| B2448FX | 24" x 48" x 2.28" | 1012 | 120.15 lbs | 176.37 lbs | 26.8" x 50.8" x 9.1" |

| B3036FX | 30" x 36" x 2.28" | 952 | 112.66 lbs | 163.14 lbs | 32.7" x 38.6" x 9.1" |

| B3048FX | 30" x 48" x 2.28" | 1288 | 150.13 lbs | 198.42 lbs | 32.7" x 50.4" x 9.1" |

| B3060FX | 30" x 60" x 2.28" | 1624 | 187.61 lbs | 253.53 lbs | 32.7" x 62.2" x 9.1" |

| B3648FX | 36" x 48" x 2.28" | 1564 | 180.12 lbs | 264.55 lbs | 38.6" x 50.4" x 9.1" |

| B3660FX | 36" x 60" x 2.28" | 1972 | 225.09 lbs | 286.60 lbs | 38.6" x 62.6" x 9.1" |

| B3672FX | 36" x 72" x 2.28" | 2380 | 269.85 lbs | 346.13 lbs | 38.6" x 74.4" x 9.1" |

Metric Breadboard Dimensions & Mass

| Item # | Dimensions (W x L x H) |

# of Tapped Holes |

Unpacked Mass |

Packaged Shipping Mass |

Packaged Dimensions |

|---|---|---|---|---|---|

| B3045AX | 300 mm x 450 mm x 58 mm | 160 | 10.1 kg | 14 kg | 370 mm x 510 mm x 140 mm |

| B3060AX | 300 mm x 600 mm x 58 mm | 220 | 13.3 kg | 20 kg | 360 mm x 660 mm x 140 mm |

| B4560AX | 450 mm x 600 mm x 58 mm | 352 | 20.0 kg | 29 kg | 510 mm x 660 mm x 140 mm |

| B6060AX | 600 mm x 600 mm x 58 mm | 484 | 26.5 kg | 43 kg | 670 mm x 670 mm x 140 mm |

| B6090AX | 600 mm x 900 mm x 58 mm | 748 | 39.7 kg | 60 kg | 660 mm x 960 mm x 230 mm |

| B60120AX | 600 mm x 1200 mm x 58 mm | 1012 | 52.9 kg | 76 kg | 660 mm x 1260 mm x 230 mm |

| B7590AX | 750 mm x 900 mm x 58 mm | 952 | 49.6 kg | 71 kg | 810 mm x 960 mm x 230 mm |

| B75120AX | 750 mm x 1200 mm x 58 mm | 1288 | 66.1 kg | 87 kg | 820 mm x 1270 mm x 230 mm |

| B75150AX | 750 mm x 1500 mm x 58 mm | 1624 | 82.6 kg | 111 kg | 810 mm x 1560 mm x 230 mm |

| B90120AX | 900 mm x 1200 mm x 58 mm | 1564 | 79.3 kg | 130 kg | 960 mm x 1260 mm x 230 mm |

| B90150AX | 900 mm x 1500 mm x 58 mm | 1972 | 99.1 kg | 129 kg | 960 mm x 1560 mm x 230 mm |

| B90180AX | 900 mm x 1800 mm x 58 mm | 2380 | 118.9 kg | 150 kg | 960 mm x 1860 mm x 230 mm |

| Posted Comments: | |

George Brown

(posted 2025-09-25 12:51:00.663) The free depth of the screw holes is just 5 mm, yet the specs say that the maximum screw depth is 54 mm (It appears that the steel skin is bonded to some kind of synthetic material). Is it intended that screws penetrate the synthetic material? spolineni

(posted 2025-09-29 10:31:13.0) Thank you for contacting us. Yes, screws are intended to extend beyond the 5 mm top skin into the tapped holes. The honeycomb core does not interfere with the holes, so you can safely use the full specified screw depth of 54 mm (16 mm for Outer Border Holes). Dusan Lorenc

(posted 2024-04-05 10:26:22.65) Dear Sir/Madam,

could you please provide some reference data on the compliance of NEXUS breadboards below 10 Hz. Specifically is there a chance that there is a bump in the curve somewhere btw. 1Hz and 10Hz?

Thank you

Dusan cstroud

(posted 2024-04-19 07:21:31.0) Thanks for reaching out. Unfortunately our testing method is unable to provide data within the 1-10Hz range. I will reach out to you to discuss this further. Srikanth Gurram

(posted 2019-09-19 21:07:28.21) Can you provide a test report for B90180AX (like you provide for nexus series breadboards)? cwright

(posted 2019-09-20 07:52:19.0) Thank you for contacting us. Unfortunately we do not have this test report as this is a specification we only measure for the Nexus range of breadboards. For comparison of the two ranges we do provide a juxtaposition of a B6090A Nexus Breadboard's curve and a B6090AX Intrinsically Damped Breadboard's curve. This will look similar for all comparably sized boards. https://www.thorlabs.com/images/TabImages/Breadboard_Intrinsic_Compliance_G2-780.gif |

| Breadboards |  Nexus, Optimized Damping |

Intrinsically Damped |

Aluminum Honeycomb |

Stainless Steel |

Solid Aluminum |

|---|---|---|---|---|---|

| Construction | |||||

| Breadboard Thickness |

60 mm (2.4") 110 mm (4.3") |

58 mm (2.28") | 25 mm (0.98") 55 mm (2.2") |

12.7 mm (0.5") | 7.0 mm (0.28") 9.5 mm (0.375") 12.7 mm (0.5") 19.05 mm (0.75") |

| Working Surface | 4003 Grade Stainless Steel or 304L Grade Non-Magnetic Steel Top Plate |

4003 Grade Stainless Steel Top Plate |

Aluminum | 416 Grade Stainless Steel | Solid Aluminum Anodized or Unanodized |

| Top Skin | 5 mm (0.20") | 5 mm (0.20") | 6 mm (0.24") | N/A | N/A |

| Bottom Skin | 5 mm (0.20") | 3 mm (0.12") | 3 mm (0.12") | N/A | N/A |

| Core Design | High-Density Plated Steel Honeycomb, 0.26 mm Thick | High-Density Plated Aluminum Honeycomb |

N/A | N/A | |

| Side Panels | Rigid Steel Box Section | Unplasticized Polyvinyl Chloride (uPVC) |

Black Laminated Aluminum Sides |

N/A | N/A |

| Ferromagnetism | Magnetic or Non-Magnetic Options | Magnetic | Non-Magnetic | Magnetic | Non-Magnetic |

| Sealed Holes | Sealed (25 mm Depth) or Non-Sealed Options |

Non-Sealed | N/A | N/A | |

| Thread Options | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 1/4"-20 (M6) Tapped Holes | 4-40 (M3), 8-32 (M4) and 1/4"-20 (M6), or 1/4"-20 (M6) Tapped Holes |

|

| Spacing | 1" (25 mm) Centers | 1" (25 mm) Centers | 1" (25 mm) Centers | 0.4" (10 mm) Centers, 0.5" (12.5 mm) Centers, or 1" (25 mm) Centers |

|

| Distance from Edge to First Holes |

0.5" (12.5 mm) on all Sides | 0.5" (12.5 mm) or 1.0" (25 mm) on all Sides |

0.5" (12.5 mm) on all Sides | 0.4" (10 mm) on all Sides or 0.5" (12.5 mm) on all Sides |

|

| Performancea | |||||

| Damping |  |

|

|

N/A | N/A |

| Stiffness |  60 mm (2.4") Thick |

58 mm (2.28") Thick |

25 mm (0.98") Thick |

12.7 mm (0.5") Thick |

7.0 mm (0.28") Thick |

110 mm (4.3") Thick |

55 mm (2.2") Thick |

19.05 mm (0.75") Thick |

|||

Optical Breadboard Selection Guides

Table 10A and Table 10B list every size offered for our honeycomb, solid aluminum, and acrylic breadboards. Simply locate the specific width and length needed and then select the type of breadboard. Expand each table by clicking the More [+] button within the header.

Thorlabs also offers several unique breadboard solutions. For applications requiring temperature control, we offer aluminum liquid-cooled breadboards and baseplates in several sizes, in addition to a temperature-controlled mini-series breadboard for small-scale applications. Our anodized aluminum large-area translation stages and rotating breadboards offer hand-operated positioning control, while our manual and motorized translating mounting platforms are ideal for use in microscopy applications.

| Table 10A Imperial Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| Table 10B Metric Optical Breadboard Size Options | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width | Length | Honeycomb | Stainless Steel | Solid Aluminuma | ||||||

| Nexus (60 mm Thick)b |

Nexus (110 mm Thick)b |

Intrinsically Damped (58 mm Thick) |

Aluminum (25 mm Thick) |

Aluminum (55 mm Thick) |

Standard | Double Density | High Density | |||

| 50 mm | 75 mm | - | - | - | - | - | - | - | - | MSB5075/M |

| 75 mm | 100 mm | - | - | - | - | - | - | - | - | MSB7510/M |

| 75 mm | 150 mm | - | - | - | - | - | - | - | - | MSB7515/M |

| 100 mm | 100 mm | - | - | - | - | - | MB10S/M | - | - | - |

| 100 mm | 150 mm | - | - | - | - | - | MB1015S/M | MB1015/M MB1015U/M |

M45B1015/Mc | MSB1015/M |

| 100 mm | 300 mm | - | - | - | - | - | - | MB1030/M | - | - |

| 100 mm | 600 mm | - | - | - | - | - | - | - | MB1060/M | - |

| 100 mm | 900 mm | - | - | - | - | - | - | - | MB1090/M | - |

| Ø149 mm | - | - | - | - | - | - | - | MBR150U/M | - | |

| Ø150 mm | - | - | - | - | - | - | - | MBR150/M | - | |

| 150 mm | 150 mm | - | - | - | - | - | MB15S/M | MB1515/M MB1515U/M |

M45B1515/Mc | MBY1515/M MSB15/M |

| 150 mm | 300 mm | - | - | - | - | - | - | MB1530F/M | MB1530/M M45B1530/Mc |

- |

| 150 mm | 450 mm | - | - | - | - | - | - | MB1545/M | - | - |

| 150 mm | 600 mm | - | - | - | - | - | - | MB1560/M | - | - |

| 150 mm | 900 mm | - | - | - | - | - | - | MB1590/M | - | - |

| 150 mm | 1200 mm | - | - | - | - | - | - | MB15120/M | - | - |

| 180 mm | 230 mm | - | - | - | - | - | - | - | - | MSB1823/M MSBU1823/M |

| 200 mm | 200 mm | - | - | - | - | - | - | MB2020/M MB2020U/M |

- | - |

| 200 mm | 250 mm | - | - | - | - | - | - | MB2025/M | - | - |

| 200 mm | 600 mm | - | - | - | - | - | - | - | MB2060/M | - |

| 200 mm | 900 mm | - | - | - | - | - | - | - | MB2090/M | - |

| 250 mm | 300 mm | - | - | - | - | - | - | MB2530/M MB2530U/M |

- | - |

| Ø300 mm | - | - | - | - | - | - | - | MBR300/M MBR300U/M |

- | |

| 300 mm | 300 mm | B3030Ad B3030Ld |

- | - | PBG3030Ae | - | - | MB3030/M MB3030U/M |

MB3030D/M | MBY3030/M MSB30/M MS12B/M |

| 300 mm | 450 mm | B3045Ad B3045Ld |

- | B3045AX | PBG3045Ae | - | - | MB3045/M MB3045A/Mf MB3045U/M |

- | MBY3045/M MSB3045/M |

| 300 mm | 600 mm | B3060Ad B3060L |

- | B3060AXd | PBG3060A | PBG52502d | - | MB3060/M MB3060U/M |

- | - |

| 300 mm | 900 mm | B3090Ad B3090Ld |

- | - | PBG3090Ae | PBG52503d | - | MB3090/M | - | - |

| 300 mm | 1200 mm | - | - | - | - | - | - | MB30120/M | - | - |

| 350 mm | 1150 mm | - | - | - | - | - | - | MB35115/M | - | - |

| 350 mm | 1425 mm | - | - | - | - | - | - | MB35142/M | - | - |

| 450 mm | 450 mm | B4545Ad B4545Ld |

- | - | PBG4545A | - | - | MB4545/M | - | - |

| 450 mm | 600 mm | B4560Ad B4560Ld |

- | B4560AXd | PBG4560Ae | PBG52522d | - | MB4560/M MB4560A/Mf MB4560U/M |

- | - |

| 450 mm | 750 mm | - | - | - | - | - | - | MB4575/M | - | - |

| 450 mm | 900 mm | - | - | - | - | - | - | MB4590/M | - | - |

| 600 mm | 600 mm | B6060Ad B6060L |

- | B6060AXd | PBG6060Ae | PBG52505d | - | MB6060/M | - | |

| 600 mm | 900 mm | B6090A B6090L B6090ANd B6090Z |

B6090Bd B6090Nd |

B6090AX | PBG6090Ae | PBG52506d | - | MB6090/M | - | - |

| 600 mm | 1200 mm | B60120A B60120L |

B60120Bd B60120Nd |

B60120AX | PBG60120Ae | - | - | MB60120/M | - | - |

| 600 mm | 1500 mm | - | B60150Bd B60150Nd |

- | - | PBG52508d | - | - | - | - |

| 750 mm | 750 mm | B7575A B7575L |

- | - | - | - | - | MB7575/M | - | - |

| 750 mm | 900 mm | B7590A B7590L B7590ANd B7590Z |

B7590Bd B7590Nd |

B7590AX | PBG7590Ae | PBG52510d | - | - | - | - |

| 750 mm | 1200 mm | B75120A B75120L B75120ANd B75120Z |

B75120B B75120Nd |

B75120AX | PBG75120Ae | PBG52511 | - | - | - | - |

| 750 mm | 1500 mm | - | B75150B B75150N |

B75150AX | - | - | - | - | - | - |

| 900 mm | 900 mm | B9090A B9090L |

B9090Bd B9090Nd |

- | - | - | - | - | - | - |

| 900 mm | 1200 mm | B90120A B90120L B90120AN B90120Z |

B90120B B90120N |

B90120AX | PBG90120Ae | PBG52513 | - | - | - | - |

| 900 mm | 1500 mm | - | B90150B B90150N |

B90150AX | - | PBG52514 | - | - | - | - |

| 900 mm | 1800 mm | - | B90180B B90180N |

B90180AX | - | - | - | - | - | - |

| 1200 mm | 1500 mm | - | B120150Bd B120150Nd |

- | - | - | - | - | - | - |

| 1200 mm | 1800 mm | - | B120180B B120180Nd |

- | - | - | - | - | - | - |

Products Home

Products Home

Breadboards, 58 mm Thick

Breadboards, 58 mm Thick