Vytran® Compact Fiber Cleaver

- Automated Fiber Cleaver for Ø60 μm to Ø600 μm Fiber Cladding

- Accepts SM, MM, PM, Photonic Crystal Fiber, Capillary

Tubes, and Soft Glass Fiber - Flat or Angled Cleaves

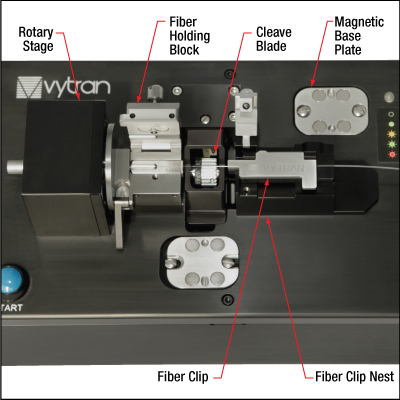

CAC400A

Fiber Cleaver with Rotary

Stage for Angled Cleaves

(Shown with a Shipping Fixture)

VHM500

Fiber Holder Clip

Selected Based on Buffer Diameter

(Required and Sold Separately)

VHL040060

VHK400500

Top and Bottom Inserts Selected Based on Cladding Diameter (Required and Sold Separately)

Please Wait

| Specifications | ||

|---|---|---|

| Item # | CAC400 | CAC400A |

| Cleave Angle | 0° | 0° to 15° |

| Cleave Angle Accuracy | ±1.0° | ±1.0° |

| Cleave Method | Tension and Scribe | |

| Maximum Axial Tensiona | 21.6 N (4.9 lbs) | |

| Fiber Cladding | Ø60 μm to Ø600 μm | |

| Fiber Buffer/Coating | Ø67 μm to Ø1200 μm | |

| Clip-to-Cleave Lengthb | 5.5 mm to 30 mm | |

| Minimum Fiber Waste Lengthc | 22 mm | |

| System Dimensions (L x W x H) | 9.25" x 5.00" x 4.70" (235.0 mm x 127.0 mm x 119.4 mm) |

|

| Weight | 4.5 lbs (2.0 kg) | |

Features

- Flat (0°) or Angled Cleaves (up to 15°) of Ø60 μm to

Ø600 μm Cladding Fiber - Programs for Cleaving Standard or Specialty Fiber:

- Single Mode (SM), Multimode (MM), and Polarization-Maintaining (PM) Fiber

- Photonic Crystal Fiber (PCF)*

- Soft Glass Fiber

- Capillary Tubes

- Parameters for Cleaving Fluoride Fiber are Available; Contact Tech Support for Details

- Fiber Clips for Loading Fiber into the Cleaver (Required and Sold Separately)

- Accepts Fiber with Ø67 μm to Ø1200 μm Buffer

- V-Groove Inserts Hold Discarded Fiber End (Required and Sold Separately)

- Accepts Fiber with Ø40 μm to Ø600 μm Cladding

- Mirror-Quality End-Face Finishes Critical for High-Performance Splicing

- Location-Specific Power Cord Included

- Contact Tech Support for Systems that Support Fujikura and Fitel Fiber Clips

Click to Enlarge

The above image shows a fiber within a clip being inserted into the CAC400A Angled Fiber Cleaver. The clip is secured by the fiber clip nest which translates, tensioning the fiber. The excess fiber is secured by a fiber holding block, which contains a top and bottom insert; each insert is selected based on the cladding diameter. A rotary stage adds a pre-programmed torsion to the fiber before tensioning it, allowing for an angled cleave. Two magnetic base plates are included to hold the CACM Micrometer Backstop and Camera Assembly.

These Vytran® Compact Automated Fiber Cleavers are designed for cleaving fibers with claddings from Ø60 μm to Ø600 μm with a high degree of accuracy, ease of use, and versatility in manufacturing or research environments. The CAC400 is designed to produce flat cleaves perpendicular to the length of the fiber, while the CAC400A has a rotation stage for creating angle cleaves up to 15°.*

Each unit operates with a tension-and-scribe cleave method, whereby axial tension is first applied to the fiber followed by an automated scribe process utilizing a diamond cleave blade. After the blade scribes the fiber, tension is maintained, causing the scribe to propagate across the fiber perimeter and complete the cleave. The CAC400A accomplishes angle cleaves by using the rotation stage to apply torsion to the fiber prior to scribing. The resulting cleave will be perpendicular to the maximum resultant stress created by the combined tension and torsion applied to the fiber. This method produces consistent low-angle cleaves with mirror-quality end-face finishes, ideal for splicing, and has a cleave angle accuracy of ±1.0°. See the Cleaving Guide tab for details.

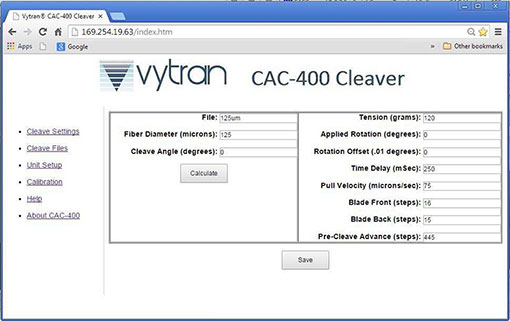

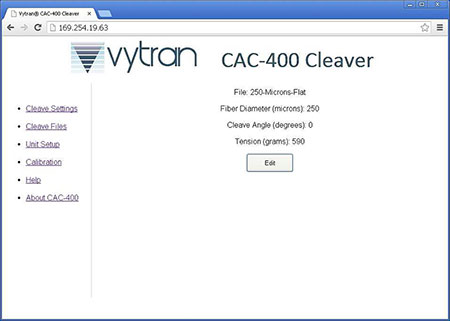

Cleaving parameters can be configured and controlled from a web interface accessible using any web browser. All that is needed is an internet connection, ethernet cable, and the provided IP address of the unit. For more details on the web-based software for the CAC400 and CAC400A Compact Cleavers, please see the Software tab.

Each cleaver includes a diamond blade for scribing the fiber. When used with proper cleave parameters, a single location on the blade can provide up to 5,000 cleaves (dependent on the cladding properties of the fiber being cleaved). The cleaver is designed so that the cleave blade can be repositioned approximately 10 times before replacement (assuming proper cleave parameters and usage that does not cause unexpected damage to the blade). For more information, please refer to the specific compact cleaver manual, which can be found by clicking on the red "Docs" icon (![]() ) below. Replacement cleave blades are available below.

) below. Replacement cleave blades are available below.

Sub-Critical Processing

The CAC400 and CAC400A web-based software includes parameters that allow for high-quality cleaves of specialty fiber such as microstructured PCF and large-diameter PM fiber or when performing an angle cleave of MM or PM fiber. This sub-critical process applies a tension that is lower than required for a "standard" cleave. The blade then scribes the fiber while the tension is being incrementally increased to propagate the scribe and produce a cleave. Since the resulting crack is allowed to propagate relatively slowly with little driving force, a smoother cleave results.

An optional CACM Micrometer Backstop and Camera Assembly is available for when a lower tension cleave is required or when cleaving large-diameter fiber. The camera provides 200X magnification, while the flat-tipped micrometer backstop prevents the fiber from buckling at low tensions when contacted by the blade. For more details on when the micrometer backstop should be used, please see the table in the Cleaving Guide tab.

Fiber Clips and Inserts (Required)

Fiber clips, available separately below, are required for loading the fiber into the CAC400 or CAC400A Fiber Cleaver. The fiber is loaded within the clip, which is then secured on a translating fiber clip nest with a clamp, as shown in the image to the right. This allows for multiple clips to be pre-loaded with fiber for faster processing times. These clips should be selected based on the fiber buffer or coating diameter.

When the clip is loaded into the system, the unmounted fiber will lay across a fiber holding block that will anchor the discarded or "waste" portion of the fiber during the cleaving process. This holding block contains a top and bottom insert, sold separately, with V-grooves designed to retain specific fiber cladding diameters. Nylon-tipped setscrews are used to secure the inserts in the fiber holding blocks; replacement 2-56, 1/8" long SS2SN013 setscrews are available in packs of 10.

*It may not be possible to create clean angle cleaves in specialty fibers with large "air-fill" fractions due to the material properties of the fiber.

Compact Fiber Cleaver Web Interface

The CAC400 and CAC400A are configured and controlled from a web interface that can be accessed from any web browser. This interface allows the user to read and modify the parameters that control the cleaving process. The user can modify default cleaving programs, as well as create new programs based on desired settings. Each of these programs, or fiber files, is saved on the unit and can be accessed any time the unit is connected to a computer.

To access the interface, simply connect the unit to any computer with internet access via the included ethernet cable, and enter 169.254.19.63, the CAC400's default IP address, into the user's web browser of choice. If the CAC400 and CAC400A systems are connected to the computer through a LAN, the IP address is assigned by the DCHP server.

Click to Enlarge

Click to EnlargeThe web interface calculates required parameters from desired fiber diameter and cleave angle.

Click to Enlarge

Click to EnlargeThe software is a simple web interface that can be accessed through any web browser.

For more information, please see the manual, which can be found by clicking on the red "Docs" icons (![]() ) by item numbers below.

) by item numbers below.

Tension-and-Scribe Cleave Process

The CAC400 and CAC400A Fiber Cleavers use the tension-and-scribe cleaving process, where tension is applied along the length of the fiber followed by an automatic scribing process utilizing a diamond cleave blade. After the blade scribes the fiber, tension is maintained, causing the scribe to propagate across the fiber width and complete the cleave. Angle scribes are accomplished in the CAC400A by using the rotation stage to apply torsion to the fiber, starting prior to commencing the "tension-and-scribe" process. The resulting cleave will be perpendicular to the maximum resultant stress created by the combined tension and torsion applied to the fiber.

Sub-Critical Process for Cleaving Specialty Fibers

Certain specialty fibers, such as photonic crystal fiber (PCF), microstructured fibers, capillary tubes, or highly stressed fibers (multimode or polarization maintaining) may require special parameters in order to create clean cleaves at the desired angle. These Vytran® fiber cleavers can be programmed with a "sub-critical" cleave process in order to produce high-quality cleaves for these fiber types.

For these cleaves, the initial tension applied to the fiber is lower than what would be required for the standard tension-and-scribe process. The optional micrometer backstop (Item # CACM) prevents the fiber from bending when it is scribed at this lower tension. After the scribe, the tension is slowly, incrementally increased, which serves to propagate the scribe across the fiber and complete the cleave. Parameters for this process can be adjusted using the web browser interface, including the starting and ending tension and how fast the tension is increased after the initial scribe.

Cleaving Guide

The following information is intended to provide a starting point when selecting the best process to use for cleaving different types of fiber. To achieve the best possible cleave results, further experimentation is typically required to fine-tune the cleave parameters for each specific fiber type.

Standard Process: This tension-and-scribe process applies a constant tension along the fiber axis. When the fiber is scribed, this tension causes the scribe to propagate across the fiber to produce the cleave.

Sub-Critical Process: This process starts with a lower tension applied to the fiber than required by the standard cleaving process. After the fiber is scribed, the tension is slowly increased until the scribe propagates across the fiber and the cleave is complete. This can improve the cleave quality in highly stressed or specialty fibers.

Micrometer Backstop: The tip of the micrometer is positioned so that it just touches the fiber, providing a surface that prevents the fiber from deforming when contacted by the cleave blade during scribing. It is particularly useful when cleaving large-diameter fibers or when using the lower-tension sub-critical process.

| Fiber Type | Cleave Type | Standard Process | Sub-Critical Process | Micrometer Backstop |

|---|---|---|---|---|

| Fiber with Cladding <Ø600 µm | Straight or Angleda | - | - | |

| Multimode Fiber | Straight | - | - | |

| Angleda | - | Use if Fiber Cladding is >Ø400 µm | ||

| Thick-Walled Capillary Tubing (Wall Thickness at Least 10% of Diameter) |

Straight or Angleda | - | - | |

| Thin-Walled Capillary Tubing (Wall Thickness <10% of Diameter) |

Straight or Angleda | - | ||

| PM Fiber | Straight | Use if Fiber Cladding is ≤Ø400 µm | Use if Fiber Cladding is >Ø400 µm | |

| Angleda | - | |||

| PCF | Straight or Angleda | - |

Product DemonstrationsThorlabs has demonstration facilitates for the Vytran® fiber glass processing systems offered on this page within our Morganville, New Jersey and Exeter, Devonshire offices. We invite you to schedule a visit to see these products in operation and to discuss the various options with a fiber processing specialist. Please schedule a demonstration at one of our locations below by contacting technical support. We welcome the opportunity for personal interaction during your visit! Thorlabs Vytran Europe

|

| Posted Comments: | |

Victor Karaganov

(posted 2021-07-04 23:33:06.79) Dear Technical Support Team,

What cleave flatness can normally be achieved with CAC400, CAC400A, LDC401, LDC401A, LDC450B cleavers for 400-600um cladding?

What is the reason that the “cleave flatness” is not explicitly specified for these cleavers?

Thank you for your help,

Victor YLohia

(posted 2021-07-09 02:53:38.0) Thank you for contacting Thorlabs. We have reached out to you directly with this information. supply

(posted 2016-06-08 09:26:11.157) Dear Sirs or Madam,

CJSC FOTEK is producer of laser medical devices for surgery in Belarus.

Also we offer to our clients sets with the lightguide tool.

Now we are looking for the device for fiber cleaving.

We are interested in your Compact Fiber Cleaver CAC400.

We examined information from your site but some questions remain uncleared.

Please help us to understand the following:

1. We would like to receive cleaves at the fiber Silica/Silica/Polyimide 600/660/690P.

Is it possible to receive cleaves without the removing of Polyimide cladding?

2. How many cleaves for the mentioned fiber could the blade provide?

3. What additional tools kit to the Compact Fiber Cleaver CAC400 is necessary for cleaving the mentioned fiber?

4. What is the minimal fiber length could be provided by your cleaver machine after the cleaving process?

5. What is the length of waste of fiber after the cleaving process?

6. Is it possible to receive the ready-made piece of fiber that cleaved from both sides from very long fiber length without waste?

There are any fiber length limitations in the left and right fixing devices?

7. What is the productive capacity of CAC400? We are interested in the quantity of cleaves per minute.

8. Do you have any video of your machine CAC400 in operation? Is it possible to see it?

Please inform us the price for CAC400 x 1 pcs and additional tools kit if they are necessary.

What is the time of readiness for shipment after order confirmation?

It would be highly appreciated if you give me reply on the questions above.

Thank you in advance,

Kind regards,

Oksana Zheludkovich

Purchasing specialist,

CJSC FOTEK

tel/fax: +375 17 385 19 22,

mob.: +375 44 795 76 11

www.mediola.by besembeson

(posted 2016-06-08 12:10:35.0) Response from Bweh at Thorlabs USA: Our Vytran specialist will contact you directly to address all your questions. |

Support for Industry-Standard

Fiber Processing Machines

Thorlabs offers compact automatic fiber cleavers that are compatible with Fujikura and Fitel fiber clips, allowing for seamless process integration into their fiber processing systems. If you would like a CAC400 or CAC400A system designed around these fiber clips, please contact Tech Support.

| Fiber Compatibility | |||

|---|---|---|---|

| Item # | Nominal Buffer Diametera |

Minimum Buffer Diameter |

Maximum Buffer Diameter |

| VHM100 | 100 μm | 67 μm | 133 μm |

| VHM165 | 165 μm | 110 μm | 220 μm |

| VHM250 | 250 μm | 167 μm | 333 μm |

| VHM325 | 325 μm | 217 μm | 433 μm |

| VHM400 | 400 μm | 267 μm | 533 μm |

| VHM500 | 500 μm | 333 μm | 667 μm |

| VHM650 | 650 μm | 433 μm | 867 μm |

| VHM900 | 900 μm | 600 μm | 1200 μm |

Click to Enlarge

VHM165 Fiber Clip in the Open Position Showing the Internal V-Groove and Magnets to Secure the Lid

- Used to Load Fiber into a CAC400 or CAC400A Fiber Cleaver

- Eight Clips for Fiber Buffers from Ø100 μm to Ø900 μm Offered

(See Table to the Right for Details) - Multiple Clips can be Pre-Loaded Before Use to Descrease Processing Time

These V-Groove Fiber Clips are used to load a fiber into a CAC400 or CAC400A Automatic Cleaver; the fiber cannot be loaded without a clip. The use of these clips allows for multiple fibers to be prepared and loaded before the cleaving process begins, greatly minimizing processing time.

Each clip's V-groove can support approximately ±33% of the nominal compatible buffer diameter. However, oversized or undersized fibers will create an offset that decenters the fiber.

Eight clips are available, each with a different V-groove size to cover a nominal fiber buffer diameter from 100 μm to 900 μm. The V-groove is able to securely hold buffer diameters up to ~33% smaller or larger than the nominal size that the clip is designed to hold; however, the fiber will no longer be centered in front of the cleaving blade as shown in the drawing to the right (see the table to the right for details).

Once the fiber is loaded, the clip is secured onto the fiber clip nest of the cleaver using a magnetic clamp. A thumscrew lock in the magnetic clamp provides a higher holding force when securing larger diameter (>500 μm) or more slippery fiber during the cleaving process. The thumbscrew will ensure that the fiber is held accurately in place without any risk of slippage when tensioned.

| Fiber Compatibility | |||||

|---|---|---|---|---|---|

| Item # | Insert Typea |

Sideb | Nominal Cladding Diameterc |

Minimum Cladding Diameter |

Maximum Cladding Diameter |

| VHL040060d | Bottom | 1 | 40 μm | 27 μm | 53 μm |

| 2 | 60 μm | 40 μm | 80 μm | ||

| VHL080125e | 1 | 80 μm | 53 μm | 107 μm | |

| 2 | 125 μm | 83 μm | 167 μm | ||

| VHL165250 | 1 | 165 μm | 110 μm | 220 μm | |

| 2 | 250 μm | 167 μm | 333 μm | ||

| VHL400550 | 1 | 400 μm | 267 μm | 533 μm | |

| 2 | 550 μm | 367 μm | 733 μm | ||

| VHK000250 | Top | 1 | Flat (No V-Groove) | 27 μmf | 200 μm |

| 2 | 250 μm | 150 μm | 350 μm | ||

| VHK400500 | 1 | 400 μm | 300 μm | 450 μm | |

| 2 | 500 μm | 400 μm | 600 μm | ||

- Secure Unused, "Cleaved" Portion of Fiber in the

CAC400 or CAC400A Fiber Cleaver - Four Bottom Inserts and Two Top Inserts are Offered

(See Table for Details) - Secured on the Top or Bottom of the Fiber Holding Block

These V-Groove Fiber Holder Inserts are used within the fiber holding block of the CAC400 or CAC400A Cleavers to secure the unused, or "waste," portion of the fiber being cleaved. Two inserts will be needed: one for the top of the fiber holding block and one for the bottom.

With the exception of the VHK000250 Top Insert*, each side of each insert is equipped with a V-groove that is sized to accept a specific fiber cladding diameter. The V-groove is able to securely hold cladding diameters up to ~33% smaller or larger than the nominal cladding diameter that the insert is designed to hold. However, the fiber will no longer be centered in front of the cleaving blade, as shown in the diagram below. When choosing an insert, the fiber cladding diameter should be within the compatible ranges provided for both the top and bottom inserts chosen. See the table to the right for details.

Click to Enlarge

Here, the top and bottom inserts are shown attached to the fiber holding block of a CAC400A Cleaver.

Each clip's V-groove can support approximately ±33% of the nominal compatible cladding diameter. However, oversized or undersized fibers will create an offset that decenters the fiber.

Once the fiber is aligned and resting within the bottom insert's V-groove, the top cover, which is holding the top insert, must be lowered onto the fiber to secure it. A lever is included with the holding block to help overcome the high clamping forces of the magnets being used. This lever should always be in the downward position when opening or closing the top cover. Otherwise, the top cover can abruptly come down onto the bottom insert, damaging the fiber. Once the lid comes to rest, it can be secured in place by gently lifting the lever.

Please note that the CAC400 and CAC400A systems are designed for cleaving Ø60 μm to Ø600 μm cladding fiber. Although some inserts can hold smaller cladding diameters than what is suppported by these systems, using a fiber that is outside of this range can result in a lower quality cleave and is not recommended. For cleaving fibers with a cladding diameter up to 1.25 mm, please see our Large-Diameter Fiber Cleavers.

* The VHK000250 Top Insert has one side with no V-groove, thereby allowing for smaller fiber cladding diameters down to 27 μm, the lower limit of our bottom inserts, to be used.

Click to Enlarge

The CACM Micrometer Backstop and Camera is attached to the front magnetic plate of the CAC400A Fiber Cleaver. The camera is being focused so that the micrometer can be properly aligned behind the fiber to support a low tension fiber cleave.

- Micrometer Backstop with Built-in Camera

- Micrometer Backstop:

- Provides a Backing for Cleaving Large-Diameter (Typically >Ø400 µm) or Specialty Fiber

- 50 µm/rev with 1 µm Graduations

- USB Camera

- Provides 200X Magnification of the Cleave Process

- Removes the Need to Use an Eye Loupe to Check for Slight Contact Between Micrometer and Fiber

- Software Included

Our CACM Micrometer Backstop with Positioning Camera should be used when cleaving highly stressed fiber or capillary tubing as well as specialty fiber that requires a lower cleave tension. It attaches directly to the front magnetic base plate of the CAC400 and CAC400A Automatic Fiber Cleavers. As shown in the image to the right, the front base plate positions the micrometer directly behind the fiber, while a back base plate is provided to store the micrometer and camera assembly while it is not in use. The front plate can be roughly aligned to ensure the backstop is positioned properly behind the fiber.

The flat-tipped micrometer backstop is primarily used when cleaving highly stressed fiber that requires a lower cleave tension or when a large-diameter fiber is used (typically >Ø400 µm). The micrometer provides support to the fiber while it is being cleaved; reducing the tension without a micrometer backstop can cause the fiber to buckle when contacted by the blade. The micrometer should be aligned directly behind the fiber being cleaved and actuated so that the tip of the micrometer just contacts the fiber.

The included USB camera magnifies the cleave area by 200X, allowing the user to ensure that the micrometer just touches the fiber prior to cleaving. This camera removes the need to use an eye loupe to confirm that this contact exists when positioning the micrometer behind the fiber. As shown in the image to the right, the camera can be focused by turning the knob on the top of the assembly. All camera software is included with the CACM system.

Compatible Systems

- CAC400 and CAC400A Fiber Cleavers

- LDC401 and LDC401A Fiber Cleavers

- LDC450B Portable Fiber Cleaver

- GPX3800, GPX3850, and GPX3900 Automated Glass Processors with Cleavers

- FFS2001 and FFS2001PT Fiber Preparation and Splicing Workstations

- FFS2001PM and FFS2001WS Fiber Preparation, Splicing,

and Proof Testing Workstations - Former Generation LDC-200 Fiber Cleaver

- Replacement Blade for Our Fiber Cleaving Systems (See List to the Right)

- 0.08" (2.0 mm) Long Diamond Blade

- User Installable

Click to Enlarge

The blade is shipped in a protective covering.

The ACL83 Diamond Cleave Blade is a replacement blade for the Vytran fiber processing systems listed to the right. Each system is shipped with a blade included.

When used with proper cleave parameters, a single location on the blade can provide up to 5,000 cleaves (dependent on the cladding properties of the fiber being cleaved). The blade can be positioned approximately 10 times before replacement (assuming proper cleave parameters and usage that does not cause unexpected damage to the blade). Blade replacement instructions for each system are provided in the user manuals.

Note: Severe damage to the blade can occur if conditions cause high stress perpendicular to the edge of the blade or if incorrect parameters are used to cleave the fiber.

Products Home

Products Home

Zoom

Zoom

SM, MM, PM Cleaver:Ø60 - Ø600 µm Cladding

SM, MM, PM Cleaver:Ø60 - Ø600 µm Cladding